Page 367 - Design of Simple and Robust Process Plants

P. 367

354 Chapter 9 Operation Optimization

Plant steady Data analysis

Data

reconciliation

Parameter

Implementation

estimation

Optimization

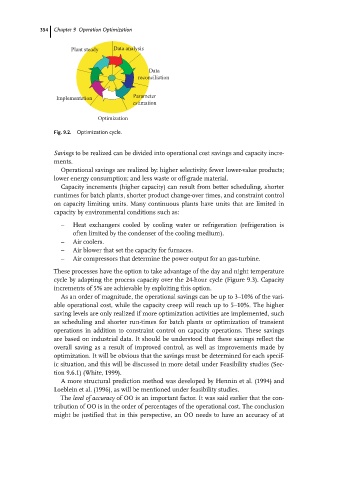

Fig. 9.2. Optimization cycle.

Savings to be realized can be divided into operational cost savings and capacity incre-

ments.

Operational savings are realized by: higher selectivity; fewer lower-value products;

lower energy consumption; and less waste or off-grade material.

Capacity increments (higher capacity)can result from better scheduling, shorter

runtimes for batch plants, shorter product change-over times, and constraint control

on capacity limiting units. Many continuous plants have units that are limited in

capacity by environmental conditions such as:

± Heat exchangers cooled by cooling water or refrigeration (refrigeration is

often limited by the condenser of the cooling medium).

± Air coolers.

± Air blower that set the capacity for furnaces.

± Air compressors that determine the power output for an gas-turbine.

These processes have the option to take advantage of the day and night temperature

cycle by adapting the process capacity over the 24-hour cycle (Figure 9.3). Capacity

increments of 5% are achievable by exploiting this option.

As an order of magnitude, the operational savings can be up to 3±10% of the vari-

able operational cost, while the capacity creep will reach up to 5±10%. The higher

saving levels are only realized if more optimization activities are implemented, such

as scheduling and shorter run-times for batch plants or optimization of transient

operations in addition to constraint control on capacity operations. These savings

are based on industrial data. It should be understood that these savings reflect the

overall saving as a result of improved control, as well as improvements made by

optimization. It will be obvious that the savings must be determined for each specif-

ic situation, and this will be discussed in more detail under Feasibility studies (Sec-

tion 9.6.1)(White, 1999).

A more structural prediction method was developed by Hennin et al. (1994)and

Loeblein et al. (1996), as will be mentioned under feasibility studies.

The level of accuracy of OO is an important factor. It was said earlier that the con-

tribution of OO is in the order of percentages of the operational cost. The conclusion

might be justified that in this perspective, an OO needs to have an accuracy of at