Page 370 - Design of Simple and Robust Process Plants

P. 370

9.4 Performance (Profit) Meter 357

Maximize

Simulated performance

Optimizer

Prices

Flows Opportunity gap

Process

model

Feeds

Products

Energy Actual performance

Prices

Process data

Process

plant

Feeds

Products

Energy

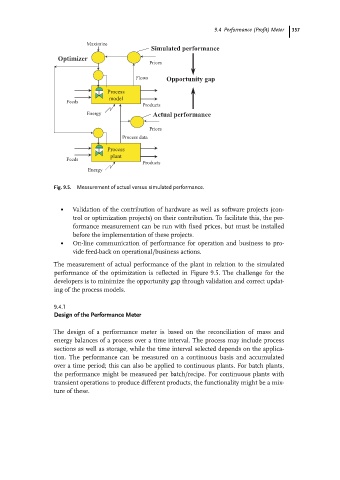

Fig. 9.5. Measurement of actual versus simulated performance.

. Validation of the contribution of hardware as well as software projects (con-

trol or optimization projects)on their contribution. To facilitate this, the per-

formance measurement can be run with fixed prices, but must be installed

before the implementation of these projects.

. On-line communication of performance for operation and business to pro-

vide feed-back on operational/business actions.

The measurement of actual performance of the plant in relation to the simulated

performance of the optimization is reflected in Figure 9.5. The challenge for the

developers is to minimize the opportunity gap through validation and correct updat-

ing of the process models.

9.4.1

Design ofthe Performance Meter

The design of a performance meter is based on the reconciliation of mass and

energy balances of a process over a time interval. The process may include process

sections as well as storage, while the time interval selected depends on the applica-

tion. The performance can be measured on a continuous basis and accumulated

over a time period; this can also be applied to continuous plants. For batch plants,

the performance might be measured per batch/recipe. For continuous plants with

transient operations to produce different products, the functionality might be a mix-

ture of these.