Page 167 - Design of Solar Thermal Power Plants

P. 167

152 3. GENERAL DESIGN OF A SOLAR THERMAL POWER PLANT

Collector tube center

2.01m

0.04m

1.00m

Glass 1 1.33m

Copper

tube Copper 2 Glass cover Copper 3 Glass 2

Copper 1 absorber tube Vacuum annulus

Cartridge heater

Exterior

disc-type

heater absorber absorber absorber absorber tube 4

Interior

tube 1 tube 2 tube 3 1.00m

disc-type

heater 1 1.67m

2.00m

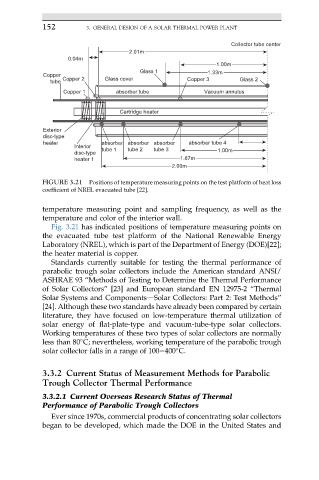

FIGURE 3.21 Positions of temperature measuring points on the test platform of heat loss

coefficient of NREL evacuated tube [22].

temperature measuring point and sampling frequency, as well as the

temperature and color of the interior wall.

Fig. 3.21 has indicated positions of temperature measuring points on

the evacuated tube test platform of the National Renewable Energy

Laboratory (NREL), which is part of the Department of Energy (DOE)[22];

the heater material is copper.

Standards currently suitable for testing the thermal performance of

parabolic trough solar collectors include the American standard ANSI/

ASHRAE 93 “Methods of Testing to Determine the Thermal Performance

of Solar Collectors” [23] and European standard EN 12975-2 “Thermal

Solar Systems and ComponentsdSolar Collectors: Part 2: Test Methods”

[24]. Although these two standards have already been compared by certain

literature, they have focused on low-temperature thermal utilization of

solar energy of flat-plate-type and vacuum-tube-type solar collectors.

Working temperatures of these two types of solar collectors are normally

less than 80 C; nevertheless, working temperature of the parabolic trough

solar collector falls in a range of 100e400 C.

3.3.2 Current Status of Measurement Methods for Parabolic

Trough Collector Thermal Performance

3.3.2.1 Current Overseas Research Status of Thermal

Performance of Parabolic Trough Collectors

Ever since 1970s, commercial products of concentrating solar collectors

began to be developed, which made the DOE in the United States and