Page 58 - Distillation theory

P. 58

P1: FCH/FFX P2: FCH/FFX QC: VINOD/IYP T1: FCH

0521820928c02 CB644-Petlyuk-v1 June 11, 2004 17:58

32 Basic Concepts of Distillation

In the case of further R increase (the second fractionation class), point x D is

traveling along side 1-2 toward vertex 1 and reaches its limiting position x D(5) at

fixed D/F parameter, when R = R 2 = R 5 (boundary mode of the second frac-

lim

t

tionation class). The tear-off point x at the second fractionation class conserves

r

its composition and the point of bottom product is traveling along the straight line

2

being parallel to side 1-2, and when R = R , it reaches side 2-3 (Fig. 2.7b).

lim

In the case of further R increase (the third fractionation class), the compositions

t

t

x D and x B do not change and the tear-off points x and x travel along sides 1-2

r s

and 2-3 toward vertex 2 until they join in this vertex (Fig. 2.7c) at R = R 7 =∞.

Under the conditions of the second fractionation class, the compositions of

products change, but the composition on the feed cross-section differs from the

composition of the feed.

In the majority of cases, the product compositions under the infinite reflux

coincide with the compositions of the product under a mode on the verge of the

second and the third classes of fractionation.

Thus, the analysis of possible compositions of the product under infinite reflux is

of practical importance and appreciably easier than the analysis under finite reflux.

2.7. Adiabatic, Nonadiabatic, and Reversible Distillation

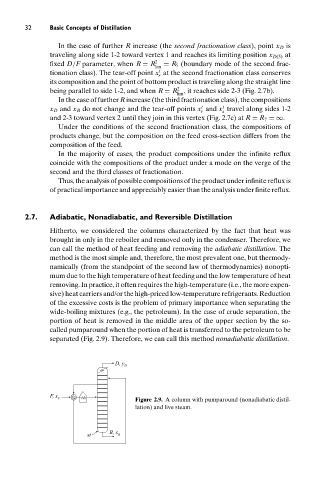

Hitherto, we considered the columns characterized by the fact that heat was

brought in only in the reboiler and removed only in the condenser. Therefore, we

can call the method of heat feeding and removing the adiabatic distillation.The

method is the most simple and, therefore, the most prevalent one, but thermody-

namically (from the standpoint of the second law of thermodynamics) nonopti-

mum due to the high temperature of heat feeding and the low temperature of heat

removing. In practice, it often requires the high-temperature (i.e., the more expen-

sive) heat carriers and/or the high-priced low-temperature refrigerants. Reduction

of the excessive costs is the problem of primary importance when separating the

wide-boiling mixtures (e.g., the petroleum). In the case of crude separation, the

portion of heat is removed in the middle area of the upper section by the so-

called pumparound when the portion of heat is transferred to the petroleum to be

separated (Fig. 2.9). Therefore, we can call this method nonadiabatic distillation.

D, y D

F, x

F

Figure 2.9. A column with pumparound (nonadiabatic distil-

lation) and live steam.

st B, x B