Page 123 - Drilling Technology in Nontechnical Language

P. 123

114 Drilling Technology in Nontechnical Language Second Edition

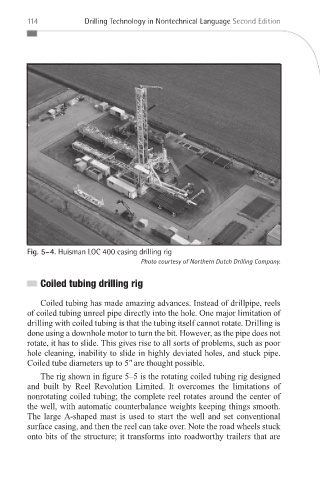

Fig. 5–4. Huisman LOC 400 casing drilling rig

Photo courtesy of Northern Dutch Drilling Company.

Coiled tubing drilling rig

Coiled tubing has made amazing advances. Instead of drillpipe, reels

of coiled tubing unreel pipe directly into the hole. One major limitation of

drilling with coiled tubing is that the tubing itself cannot rotate. Drilling is

done using a downhole motor to turn the bit. However, as the pipe does not

rotate, it has to slide. This gives rise to all sorts of problems, such as poor

hole cleaning, inability to slide in highly deviated holes, and stuck pipe.

Coiled tube diameters up to 5" are thought possible.

The rig shown in figure 5–5 is the rotating coiled tubing rig designed

and built by Reel Revolution Limited. It overcomes the limitations of

nonrotating coiled tubing; the complete reel rotates around the center of

the well, with automatic counterbalance weights keeping things smooth.

The large A-shaped mast is used to start the well and set conventional

surface casing, and then the reel can take over. Note the road wheels stuck

onto bits of the structure; it transforms into roadworthy trailers that are

_Devereux_Book.indb 114 1/16/12 2:08 PM