Page 219 - Drilling Technology in Nontechnical Language

P. 219

210 Drilling Technology in Nontechnical Language Second Edition

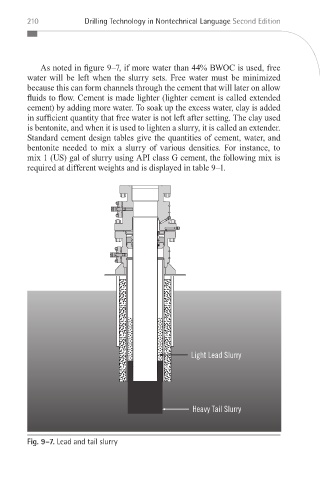

As noted in figure 9–7, if more water than 44% BWOC is used, free

water will be left when the slurry sets. Free water must be minimized

because this can form channels through the cement that will later on allow

fluids to flow. Cement is made lighter (lighter cement is called extended

cement) by adding more water. To soak up the excess water, clay is added

in sufficient quantity that free water is not left after setting. The clay used

is bentonite, and when it is used to lighten a slurry, it is called an extender.

Standard cement design tables give the quantities of cement, water, and

bentonite needed to mix a slurry of various densities. For instance, to

mix 1 (US) gal of slurry using API class G cement, the following mix is

required at different weights and is displayed in table 9–1.

Fig. 9–7. Lead and tail slurry

_Devereux_Book.indb 210 1/16/12 2:11 PM