Page 220 - Drilling Technology in Nontechnical Language

P. 220

Chapter 9 – CASING AND CEMENTING 211

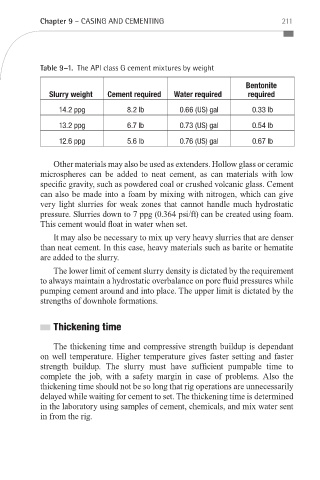

Table 9–1. The API class G cement mixtures by weight

Bentonite

Slurry weight Cement required Water required required

14.2 ppg 8.2 lb 0.66 (US) gal 0.33 lb

13.2 ppg 6.7 lb 0.73 (US) gal 0.54 lb

12.6 ppg 5.6 lb 0.76 (US) gal 0.67 lb

Other materials may also be used as extenders. Hollow glass or ceramic

microspheres can be added to neat cement, as can materials with low

specific gravity, such as powdered coal or crushed volcanic glass. Cement

can also be made into a foam by mixing with nitrogen, which can give

very light slurries for weak zones that cannot handle much hydrostatic

pressure. Slurries down to 7 ppg (0.364 psi/ft) can be created using foam.

This cement would float in water when set.

It may also be necessary to mix up very heavy slurries that are denser

than neat cement. In this case, heavy materials such as barite or hematite

are added to the slurry.

The lower limit of cement slurry density is dictated by the requirement

to always maintain a hydrostatic overbalance on pore fluid pressures while

pumping cement around and into place. The upper limit is dictated by the

strengths of downhole formations.

Thickening time

The thickening time and compressive strength buildup is dependant

on well temperature. Higher temperature gives faster setting and faster

strength buildup. The slurry must have sufficient pumpable time to

complete the job, with a safety margin in case of problems. Also the

thickening time should not be so long that rig operations are unnecessarily

delayed while waiting for cement to set. The thickening time is determined

in the laboratory using samples of cement, chemicals, and mix water sent

in from the rig.

_Devereux_Book.indb 211 1/16/12 2:11 PM