Page 230 - Drilling Technology in Nontechnical Language

P. 230

Chapter 9 – CASING AND CEMENTING 221

line up with the threads on the female end (top of the previous joint). The

connection can be rotated but the threads become damaged and will not

fully make up, so it has to be unscrewed again. The threads may be so

badly damaged that both of the casing joints have to be taken off again and

replaced. It is not an easy job to run big casings!

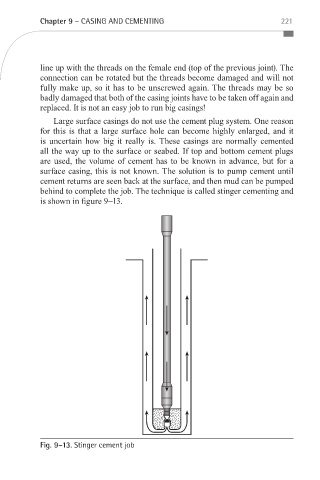

Large surface casings do not use the cement plug system. One reason

for this is that a large surface hole can become highly enlarged, and it

is uncertain how big it really is. These casings are normally cemented

all the way up to the surface or seabed. If top and bottom cement plugs

are used, the volume of cement has to be known in advance, but for a

surface casing, this is not known. The solution is to pump cement until

cement returns are seen back at the surface, and then mud can be pumped

behind to complete the job. The technique is called stinger cementing and

is shown in figure 9–13.

Fig. 9–13. Stinger cement job

_Devereux_Book.indb 221 1/16/12 2:12 PM