Page 231 - Drilling Technology in Nontechnical Language

P. 231

222 Drilling Technology in Nontechnical Language Second Edition

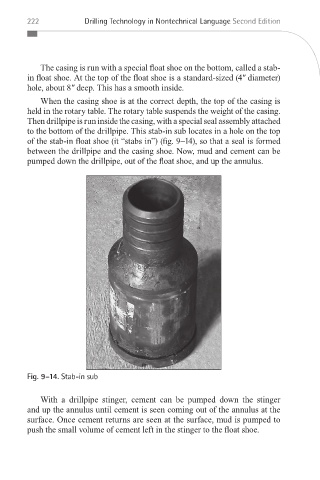

The casing is run with a special float shoe on the bottom, called a stab-

in float shoe. At the top of the float shoe is a standard-sized (4" diameter)

hole, about 8" deep. This has a smooth inside.

When the casing shoe is at the correct depth, the top of the casing is

held in the rotary table. The rotary table suspends the weight of the casing.

Then drillpipe is run inside the casing, with a special seal assembly attached

to the bottom of the drillpipe. This stab-in sub locates in a hole on the top

of the stab-in float shoe (it “stabs in”) (fig. 9–14), so that a seal is formed

between the drillpipe and the casing shoe. Now, mud and cement can be

pumped down the drillpipe, out of the float shoe, and up the annulus.

Fig. 9–14. Stab-in sub

With a drillpipe stinger, cement can be pumped down the stinger

and up the annulus until cement is seen coming out of the annulus at the

surface. Once cement returns are seen at the surface, mud is pumped to

push the small volume of cement left in the stinger to the float shoe.

_Devereux_Book.indb 222 1/16/12 2:12 PM