Page 236 - Dust Explosions in the Process Industries

P. 236

208 Dust Explosions in the Process Industries

3. Equation (3.10) is generally applicablefor relating the macroscopic tensile and shear

strength of the bulk powder to the corresponding microscopic interparticle forces.

4. Breakdown of interparticleadhesion occurs at a critical ratio between shear force and

compressive force, defining the internal angle of friction of the powder bed.

The theory predicts yield loci (see Section 3.4.2.1) for a bulk powder, with the corre-

sponding cohesion and tensile strength values as a function of the degree of compaction

(or porosity E). Encouraging agreement between experiments and theoreticalprediction

was found for a cohesive barite powder.

3.4.2

MEASUREMENT OF THE MECHANICAL STRENGTH

OF COHESIVE BULK POWDERSAND DUSTS

3.4.2.1

Basic Concepts

If a sample of dry sand is subjectedto a compressiveforce, the volume reduction, or reduc-

tion in the porosity E, is very small. Furthermore, as soon as the compressive force is

released, the sand flows freely again. Such behavior is characteristicof noncohesivepow-

ders, in which interparticleforces of the nature discussed in Section 3.3 play little or no

role compared with gravity. If, however, a sample of finer dust or powder, such as an

organic pigment, is subjected to compression,the powder sample shrinks and the poros-

ity E is reduced. Removal of the compressive force does not cause the powder sample

to return to its original state of loose packing, rather it maintains a lower porosity and

sticks together as a lump. The larger the compressiveforce is, the lower the resulting E

and the stronger the powder sample becomes.

The science of powder mechanics, which deals with these relationships in a system-

atic way, was established by the pioneering work of Jenike (1964). Jenike used

Sokolovski’s (1960) theory of the statics of soils as his starting point. Schwedes (1976)

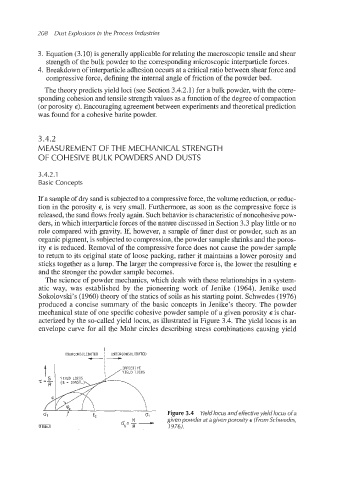

produced a concise summary of the basic concepts in Jenike’s theory. The powder

mechanical state of one specific cohesive powder sample of a given porosity E is char-

acterized by the so-called yield locus, as illustrated in Figure 3.4. The yield locus is an

envelope curve for all the Mohr circles describing stress combinations causing yield

I

OVERCONSOLIDATED I UNDERCONSOLIDATED

-1-

I

GT Gi Figure 3.4 Yield locus and effective yield locus of a

N

c;=-----t given powder at a givenporosity E (From Schwedes,

rn N R 1976).