Page 238 - Dust Explosions in the Process Industries

P. 238

2 10 Dust Explosions in the Process Industries

byf,(E), c(E), or or(€) (Figure 3.4). The Jenike shear cell gives a measure off,(€). The

value of C(E)can be estimated only by extrapolating Jenike cell failure loci to 0, = 0,

which may be uncertain, whereas or(E)cannot be determined by the Jenike shear cell.

A detailed standardized procedure for conducting the Jenike shear cell tests has been

worked out via international cooperation (EFCE Working Party on the Mechanics of

Particulate Solids, 1989).

The validity off,(€) from the Jenike shear cell in absolute terms has been questioned.

Arthur, Dunstan, and Enstad (1985) developed a biaxial test apparatusthat enables more-

direct measurement off,(€), right down to very low consolidation stresses, wheref,= 0,.

3.4.2.3

Tensile Strength Testers

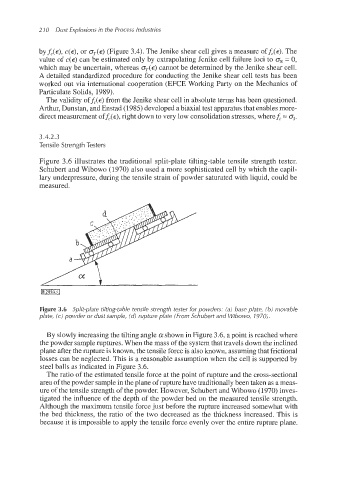

Figure 3.6 illustrates the traditional split-plate tilting-table tensile strength tester.

Schubert and Wibowo (1970) also used a more sophisticated cell by which the capil-

lary underpressure, during the tensile strain of powder saturated with liquid, could be

measured.

Figure 3.6 Split-plate tilting-table tensile strength tester for powders: (a) base plate, (b) movable

plate, (c)powder or dust sample, (d) rupture plate (From Schubert and Wibowo, 1970).

By slowly increasingthe tilting angle a shown in Figure 3.6, a point is reached where

the powder sampleruptures. When the mass of the system that travels down the inclined

plane after the rupture is known, the tensile force is also known, assuming that frictional

losses can be neglected. This is a reasonable assumption when the cell is supported by

steel balls as indicated in Figure 3.6.

The ratio of the estimated tensile force at the point of rupture and the cross-sectional

area of the powder samplein the plane of rupture have traditionallybeen taken as a meas-

ure of the tensile strength of the powder. However, Schubertand Wibowo (1970) inves-

tigated the influence of the depth of the powder bed on the measured tensile strength.

Although the maximum tensile force just before the rupture increased somewhat with

the bed thickness, the ratio of the two decreased as the thickness increased. This is

because it is impossible to apply the tensile force evenly over the entire rupture plane.