Page 260 - Dust Explosions in the Process Industries

P. 260

232 Dust Explosions in the Process Industries

Geldart and Wong (1984) also found a correlation similar to equation (3.33) using the

--n - 1.65[ -1 0.132

superficial gas velocity v,:

4.65 (3.34)

Expansion of beds of cohesive powders is caused by proliferation and enlargement of

horizontal and inclined cracks. Powders become more cohesive as the particle size is

reduced. For any given superficial air velocity, Geldart and Wong (1984) found that the

bed expansionratio (or ratio of E after and before expansion) increased with decreasing

mean particle size down to about 12pm. However, a further decrease of the particle size

caused the bed expansion ratio to drop markedly. This was attributed to the generation

of vertical cracks and channels in very cohesive powders. (See also Section 9.2.2.4.)

3.7

DISPERSION OF AGGLOMERATES OF COHESIVE

PARTICLES SUSPENDED IN A GAS BY FLOW

THROUGH A NARROW NOZZLE

The effective “particles” in clouds of very fine, cohesive dusts often are large agglom-

erates of primary particles rather than the small primary particles themselves. Depending

on the actual degree of dispersion, or deagglomeration, the effective particle size distri-

bution in the dust cloud can differ considerably for the same cohesive powder. This

results in correspondingdifferences in both ignition sensitivity and explosibility of the

dust cloud, because an agglomerate behaves as a single particle of the agglomerate size.

Bryant (1973) studied the degree of agglomeration of fine boron carbide particles of

diameters 1pm or less, dispersed as a cloud in a gas. He generated the cloud by blow-

ing dust through a narrow nozzle and measured the mean effective “particle” size (agglom-

erates) as a function of the injectionpressure (injectionvelocity).At a pressure of 3.5 bar(g),

the mean diameter of the particles in the cloud was 6.2 pn; whereas at 7 bar(&, it had

been reduced to 3.5 pm.

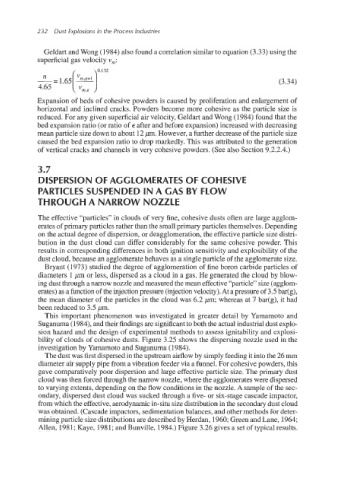

This important phenomenon was investigated in greater detail by Yamamoto and

Suganuma (1984), and their findings are significantto both the actual industrial dust explo-

sion hazard and the design of experimental methods to assess ignitability and explosi-

bility of clouds of cohesive dusts. Figure 3.25 shows the dispersing nozzle used in the

investigationby Yamamoto and Suganuma (1984).

The dust was first dispersedin the upstream airflow by simply feeding it into the 26 mm

diameter air supply pipe from a vibration feeder via a funnel. For cohesivepowders, this

gave comparatively poor dispersion and large effective particle size. The primary dust

cloud was then forced through the narrow nozzle, where the agglomerateswere dispersed

to varying extents, depending on the flow conditions in the nozzle. A sample of the sec-

ondary, dispersed dust cloud was sucked through a five- or six-stage cascade impactor,

from which the effective,aerodynamic in-situ size distributionin the secondary dust cloud

was obtained. (Cascade impactors,sedimentationbalances, and other methods for deter-

mining particle size distributions are described by Herdan, 1960; Green and Lane, 1964;

Allen, 1981; Kaye, 1981;and Bunville, 1984.) Figure 3.26 gives a set of typical results.