Page 270 - Dust Explosions in the Process Industries

P. 270

242 Dust Explosions in the Process Industries

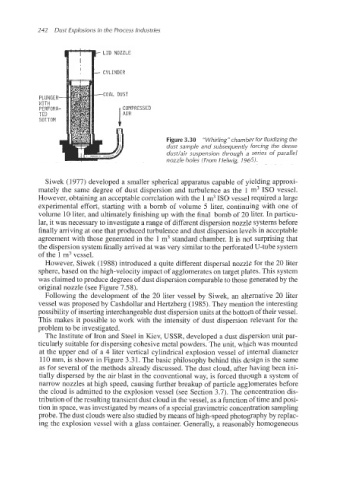

LID NOZZLE

CYLINDER

-COAL DUST

Figure 3.30 "Whirling" chamber for fluidizing the

dust sample and subsequently forcing the dense

dudair suspension through a series of parallel

nozzle holes (From Helwig, 1965).

Siwek (1977) developed a smaller spherical apparatus capable of yielding approxi-

mately the same degree of dust dispersion and turbulence as the 1 m3 IS0 vessel.

However, obtaining an acceptable correlation with the 1m3IS0 vessel required a large

experimental effort, starting with a bomb of volume 5 liter, continuing with one of

volume 10 liter, and ultimately finishing up with the final bomb of 20 liter. In particu-

lar, it was necessary to investigate a range of different dispersion nozzle systems before

finally arriving at one that produced turbulence and dust dispersion levels in acceptable

agreement with those generated in the 1 m3 standard chamber. It is not surprising that

the dispersion system finally arrived at was very similar to the perforated U-tube system

of the 1 m3vessel.

However, Siwek (1988) introduced a quite different dispersal nozzle for the 20 liter

sphere, based on the high-velocity impact of agglomerates on target plates. This system

was claimed to produce degrees of dust dispersion comparableto those generated by the

original nozzle (see Figure 7.58).

Following the development of the 20 liter vessel by Siwek, an alternative 20 liter

vessel was proposed by Cashdollar and Hertzberg (1985). They mention the interesting

possibility of inserting interchangeabledust dispersion units at the bottom of their vessel.

This makes it possible to work with the intensity of dust dispersion relevant for the

problem to be investigated.

The Institute of Iron and Steel in Kiev, USSR, developed a dust dispersion unit par-

ticularly suitable for dispersing cohesive metal powders. The unit, which was mounted

at the upper end of a 4 liter vertical cylindrical explosion vessel of internal diameter

110 mm, is shown in Figure 3.31. The basic philosophy behind this design is the same

as for several of the methods already discussed. The dust cloud, after having been ini-

tially dispersed by the air blast in the conventional way, is forced through a system of

narrow nozzles at high speed, causing further breakup of particle agglomerates before

the cloud is admitted to the explosion vessel (see Section 3.7). The concentration dis-

tribution of the resulting transient dust cloud in the vessel, as a function of time and posi-

tion in space, was investigated by means of a special gravimetric concentration sampling

probe. The dust clouds were also studiedby means of high-speed photographyby replac-

ing the explosion vessel with a glass container. Generally, a reasonably homogeneous