Page 339 - Dust Explosions in the Process Industries

P. 339

308 Dust Explosions in the Process Industries

As pointed out by Burgoyne (1963), equation (4.65) also applies to downward flame

propagation, but then v,,being numericallythe same as for upward propagation,becomes

negative.As a consequence, C, for downward propagation becomes larger than C,, and

Cs,upwards ck < Cs,downwards (4.66)

Hartmann and Nagy (1944) introduced an arbitrary pressure criterion when determin-

ing the minimum explosible dust concentration using the 1.2 liter Hartmann tube. The

top of the tube was closed by a paper membrane of bursting strength about 0.2 bar(g).

The smallestquantity of dispersed dust that generated at least this pressure rise, divided

by the volume of the tube, was taken as the minimum explosible dust concentration.

The continued use of this criterion in the extensive later investigations by the U.S.

Bureau of Mines (USBM), was confirmedby Dorsett et al. (1960). However, Cashdollar

and Hertzberg (1985) reconsidered the original USBM method and suggested their new

20 liter closed explosion vessel test as an alternative. The explosion criterion chosen was

P,/Po 2 2, where P, is the maximum absolute explosionpressure in the experiment and

Po is the initial pressure, both corrected for the pressure rise due to the 2.5-5 kJchemi-

cal ignitors used. By adopting this method, Cashdollar,Hertzberg, and Zlochower (1989)

identifiedthe minimum explosible concentration of Pittsburgh coal to about 90 g/m3,in

contrast to the earlier value of 135 g/m3 found in an 8 liter bomb and reported by

Hertzberg, Cashdollar, and Opferman (1979). Cashdollar et al. (1988) correlated mini-

mum explosible dust concentrations of coal dusts measured in the USBM 20 liter bomb

with values from large-scale mine experiments and found good agreement.

Hertzberg et al. (1987) postulated that flames in low-concentration clouds of organic

dusts and coal dusts of small particle sizes are essentially premixed gas flames. This is

because the burning velocity close to the minimum explosible concentration is so low

that each particle becomes completely devolatilized and the volatiles mixed with air in

the preheating zone of the flame front before combustion gets under way.

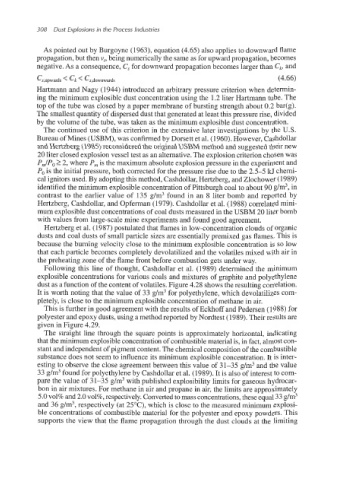

Following this line of thought, Cashdollar et al. (1989) determined the minimum

explosible concentrations for various coals and mixtures of graphite and polyethylene

dust as a function of the content of volatiles. Figure 4.28 shows the resulting correlation.

It is worth noting that the value of 33 g/m3for polyethylene, which devolatilizes com-

pletely, is close to the minimum explosible concentration of methane in air.

This is further in good agreement with the results of Eckhoff and Pedersen (1988) for

polyester and epoxy dusts, using a method reported by Nordtest (1989). Their results are

given in Figure 4.29.

The straight line through the square points is approximately horizontal, indicating

that the minimum explosibleconcentrationof combustiblematerial is, in fact, almost con-

stant and independent of pigment content.The chemical composition of the combustible

substance does not seem to influence its minimum explosible concentration.It is inter-

esting to observe the close agreement between this value of 31-35 g/m3and the value

33 g/m3found for polyethyleneby Cashdollaret al. (1989). It is also of interest to com-

pare the value of 31-35 g/m3with published explosibility limits for gaseous hydrocar-

bon in air mixtures. For methane in air and propane in air,the limits are approximately

5.0 vol% and 2.0 vol%, respectively. Convertedto mass concentrations,these equal 33 g/m3

and 36 g/m3,respectively (at 25"C), which is close to the measured minimum explosi-

ble concentrations of combustible material for the polyester and epoxy powders. This

supports the view that the flame propagation through the dust clouds at the limiting