Page 391 - Dust Explosions in the Process Industries

P. 391

360 Dust Explosions in the Process Industries

higher with venting than without. This can be explained in terms of the higher flow

velocity in the tube, due to the explosion, with a vent than without. Following ignition

close to the dust feeder, the vent opened when the flame propagated only part of the dis-

tance to the vent. The result was a sudden increase of the flow rate of the unburned cloud

ahead of the flame and a corresponding increase of the turbulence in this cloud.

Consequently, when the flame reached these turbulent regions, the combustion rate

increased markedly. Under such circumstances, the flow out of the vent can easily

become choked and very high explosion pressures can result. The combustion rate also

increases because the pressure of the unburned cloud ahead of the flame increases.

Radandt’s investigationproduced much valuable empirical data, which, however, reem-

phasizes the need for a unified computer-based model that accounts for the coupling

between gas dynamics and turbulent combustion in complex systems. Works aimed at

developing such models are reviewed in Section 9.2.4.7 in Chapter 9.

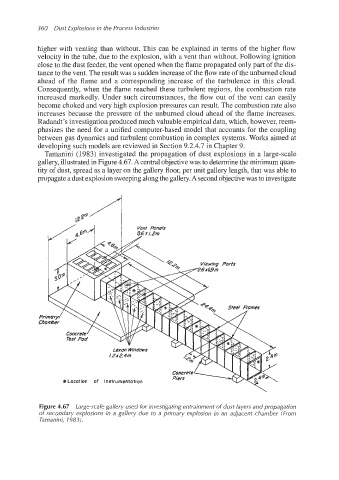

Tamanini (1983) investigated the propagation of dust explosions in a large-scale

gallery, illustrated in Figure 4.67.A central objectivewas to determinethe minimum quan-

tity of dust, spread as a layer on the gallery floor, per unit gallery length, that was able to

propagate a dust explosion sweepingalong the gallery.A secondobjectivewas to investigate

LZx24m

*Location of Instrumentotion

Figure 4.67 Large-scale gallery used for investigating entrainment of dust layers and propagation

of secondary explosions in a gallery due to a primary explosion in an adjacent chamber (From

Tamanini, 7983).