Page 470 - Dust Explosions in the Process Industries

P. 470

Sizing of Dust Explosion Vents 437

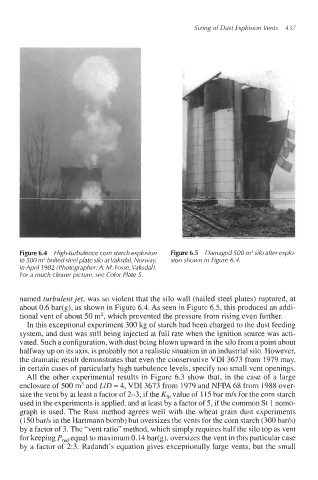

Figure 6.4 High-turbulence corn starch explosion Figure 6.5 Damaged 500 m3 silo after explo-

in 500 m3 boltedsteelplate silo at Vaksdal, Norway, sion shown in Figure 6.4.

in April 7 982 (Photographer: A. M. Fosse, Vaksdal).

For a much clearer picture, see Color Plate 5.

named turbulent jet, was so violent that the silo wall (nailed steel plates) ruptured, at

about 0.6 bar(g), as shown in Figure 6.4. As seen in Figure 6.5, this produced an addi-

tional vent of about 50 m2, which prevented the pressure from rising even further.

In this exceptional experiment 300 kg of starch had been charged to the dust feeding

system, and dust was still being injected at full rate when the ignition source was acti-

vated. Such a configuration, with dust being blown upward in the silo from a point about

halfway up on its axis, is probably not a realistic situation in an industrial silo. However,

the dramatic result demonstrates that even the conservative VDI 3673 from 1979 may,

in certain cases of particularly high turbulence levels, specify too small vent openings.

All the other experimental results in Figure 6.3 show that, in the case of a large

enclosure of 500 m3 and LID = 4, VDI 3673 from 1979 and NFPA 68 from 1988 over-

size the vent by at least a factor of 2-3, if the &, value of 115 bar m/s for the corn starch

used in the experiments is applied, and at least by a factor of 5, if the common St 1 nomo-

graph is used. The Rust method agrees well with the wheat grain dust experiments

(150 bark in the Hartmann bomb) but oversizes the vents for the corn starch (300 bark)

by a factor of 3. The “vent ratio” method, which simply requires half the silo top as vent

for keeping Pred equal to maximum 0.14 bar&), oversizes the vent in this particular case

by a factor of 2:3. Radandt’s equation gives exceptionally large vents, but the small