Page 492 - Dust Explosions in the Process Industries

P. 492

Sizing of Dust Explosion Vents 459

In most cases, the two processes are coupled via expansion-induced flow of the dust

cloud ahead of the flame, which increases the turbulence of the unburned dust cloud and

hence its burning rate. In a comprehensive theory of dust explosion venting, it is neces-

sary to include a mathematical description of this complex coupling. As discussed in

Chapter 4, this has to some extent been possible in advanced modeling of gas explosions

in complex geometries, where the turbulence is generated by flow past comparatively

large geometric obstacles. It is to be expected that the current rapid progress in gas and

dust explosion modeling will soon result in comprehensive theories and computer sim-

ulation codes for conventional venting configurations in the process industry. Further

works on this subject are reviewed in Sections 9.2.4.7,9.2.4.8, and 9.3.7.5 in Chapter 9.

However, in the meantime, several less-comprehensive, more-approximate theories are

in use, in which it is assumed that the burning of the dust cloud and the flow out of the

vent can be regarded as independent processes. In all the theories traced, it is assumed

that the burning rate of the dust cloud in the vented enclosure can, in some way or other,

be derived from the burning rate of the same dust in a standard closed-bomb test. The

theories vary somewhat in the way in which this derivation is performed, but in general

none of the existing venting theories seem to handle the complex burning rate problem

satisfactorily. As Table 4.13 in Chapter 4 shows, K,, values from dust explosions with

the same dust in closed bombs of various volumes and design can vary substantially,

depending on dust concentration, degree of dust dispersion, and dust cloud turbulence.

When using a given K,, value, or a maximum-rate-of-pressure-rise value, as input to

the various existing theories, the relevance of the laboratory test conditions yielding the

value, in relation to the dust cloud state in the actual industrial situation to be simulated,

must be evaluated. See also Section 9.2.4.8 in Chapter 9 for further approximate theories.

The second part of the venting theories, describing the flow out of the vent, is gener-

ally based on the classical, well-established theory for flow of gases through orifices.

A third common feature of existing theories is the use of the fact that, at the maximum

explosion pressure, Pred,in the vented enclosure, the first derivative of pressure versus

time is 0. This means that the rate of expansion of the dust cloud inside the enclosure

due to the combustion equals the rate of flow through the vent. An alternative formula-

tion is that the incremental pressure rise due to combustion equals the incremental pres-

sure drop due to venting.

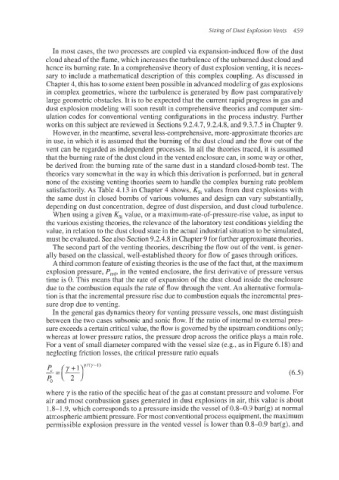

In the general gas dynamics theory for venting pressure vessels, one must distinguish

between the two cases subsonic and sonic flow. If the ratio of internal to external pres-

sure exceeds a certain critical value, the flow is governed by the upstream conditions only;

whereas at lower pressure ratios, the pressure drop across the orifice plays a main role.

For a vent of small diameter compared with the vessel size (e.g., as in Figure 6.18) and

neglecting friction losses, the critical pressure ratio equals

where y is the ratio of the specific heat of the gas at constant pressure and volume. For

air and most combustion gases generated in dust explosions in air, this value is about

1.8-1.9, which corresponds to a pressure inside the vessel of 0.8-0.9 bar(g) at normal

atmospheric ambient pressure. For most conventional process equipment, the maximum

permissible explosion pressure in the vented vessel is lower than 0.8-0.9 bar(g), and