Page 553 - Dust Explosions in the Process Industries

P. 553

520 Dust Explosions in the Process Industries

two factors tend to cancel each other, and this may be the reason for the surprisingly good

agreement obtained in some cases between MEC values from the traditional small-scale

lab test and large-scale experiments. For example, Jacobson et al. (1961) found that var-

ious grain dusts and starches all had MECs on the order of 50 g/m3in the small lab-scale

test, which compares favorably with the value 60 g/m3found for a typical wheat grain dust

containing 10% moisture in industrial-scale experiments by Eckhoff and Fuhre (1975).

However, such good agreementbetween the small-scaletest and large-scale conditions

would not be expected to be the general rule. For this reason, considerableefforts have

been made in severalcountriesduring the 1980sto develop an improved test for the MEC.

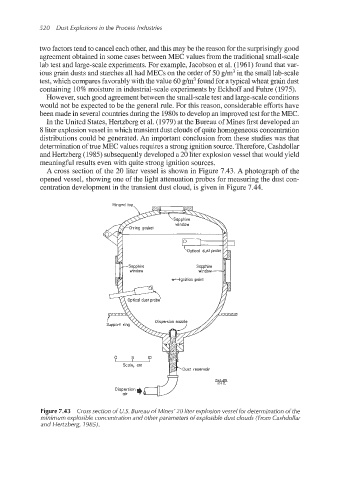

In the United States, Hertzberg et al. (1979) at the Bureau of Mines first developed an

8 liter explosionvessel in which transient dust clouds of quite homogeneous concentration

distributions could be generated. An important conclusion from these studies was that

determinationof true MEC values requires a strong ignition source.Therefore,Cashdollar

and Hertzberg (1985) subsequentlydeveloped a 20 liter explosionvessel that would yield

meaningful results even with quite strong ignition sources.

A cross section of the 20 liter vessel is shown in Figure 7.43. A photograph of the

opened vessel, showing one of the light attenuation probes for measuring the dust con-

centration development in the transient dust cloud, is given in Figure 7.44.

PGH-53

1012

Dispersion

air

Figure 7.43 Cross section of US.Bureau of Mines'2O liter explosion vessel for determination of the

minimum explosible concentration and other parameters of explosible dust clouds (From Cashdollar

and Hertzberg, 7985).