Page 566 - Dust Explosions in the Process Industries

P. 566

Assessment of lgnitability 533

Siwek sphere provided the dust dispersion and ignition conditions were the same in both

vessels.

The 20 liter vessel system described by Burke (1988) was shown to be in accordance

with the standard specified by American Society for Testing and Materials (1988c), for

determination of both maximum explosion pressures and maximum rates of pressure

rise.

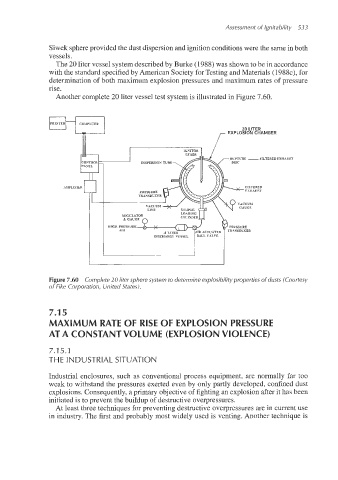

Another complete 20 liter vessel test system is illustrated in Figure 7.60.

20 LITER

EXPLOSION CHAMBER

RCPTUXE -FILTERED EXHAUST

DISPERSION TUBE

Figure 7.60 Complete20 liter sphere system to determine explosibility properties ofdusts (Courtesy

of Fike Corporation, United States).

7.1 5

MAXIMUM RATE OF RISE OF EXPLOSION PRESSURE

AT A CONSTANTVOLUME (EXPLOSIONVIOLENCE)

7.1 5.1

THE INDUSTRIAL SITUATION

Industrial enclosures, such as conventional process equipment, are normally far too

weak to withstand the pressures exerted even by only partly developed, confined dust

explosions. Consequently, a primary objective of fighting an explosion after it has been

initiated is to prevent the buildup of destructive overpressures.

At least three techniques for preventing destructive overpressures are in current use

in industry. The first and probably most widely used is venting. Another technique is