Page 188 - Electric Drives and Electromechanical Systems

P. 188

182 Electric Drives and Electromechanical Systems

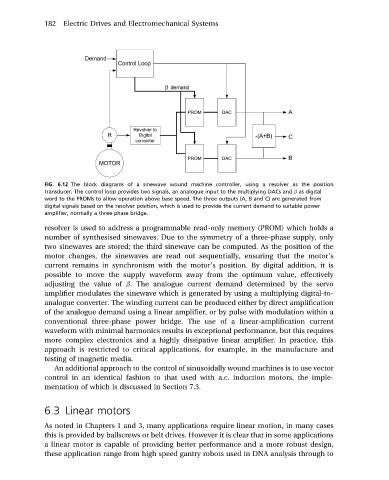

FIG. 6.12 The block diagrams of a sinewave wound machine controller, using a resolver as the position

transducer. The control loop provides two signals, an analogue input to the multiplying DACs and b as digital

word to the PROMs to allow operation above base speed. The three outputs (A, B and C) are generated from

digital signals based on the resolver position, which is used to provide the current demand to suitable power

amplifier, normally a three phase bridge.

resolver is used to address a programmable read-only memory (PROM) which holds a

number of synthesised sinewaves. Due to the symmetry of a three-phase supply, only

two sinewaves are stored; the third sinewave can be computed. As the position of the

motor changes, the sinewaves are read out sequentially, ensuring that the motor’s

current remains in synchronism with the motor’s position. By digital addition, it is

possible to move the supply waveform away from the optimum value, effectively

adjusting the value of b. The analogue current demand determined by the servo

amplifier modulates the sinewave which is generated by using a multiplying digital-to-

analogue converter. The winding current can be produced either by direct amplification

of the analogue demand using a linear amplifier, or by pulse with modulation within a

conventional three-phase power bridge. The use of a linear-amplification current

waveform with minimal harmonics results in exceptional performance, but this requires

more complex electronics and a highly dissipative linear amplifier. In practice, this

approach is restricted to critical applications, for example, in the manufacture and

testing of magnetic media.

An additional approach to the control of sinusoidally wound machines is to use vector

control in an identical fashion to that used with a.c. induction motors, the imple-

mentation of which is discussed in Section 7.3.

6.3 Linear motors

As noted in Chapters 1 and 3, many applications require linear motion, in many cases

this is provided by ballscrews or belt drives. However it is clear that in some applications

a linear motor is capable of providing better performance and a more robust design,

these application range from high speed gantry robots used in DNA analysis through to