Page 22 - Electric Drives and Electromechanical Systems

P. 22

14 Electric Drives and Electromechanical Systems

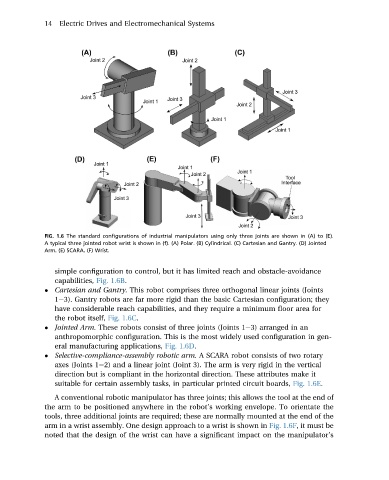

FIG. 1.6 The standard configurations of industrial manipulators using only three joints are shown in (A) to (E).

A typical three jointed robot wrist is shown in (f). (A) Polar. (B) Cylindrical. (C) Cartesian and Gantry. (D) Jointed

Arm. (E) SCARA. (F) Wrist.

simple configuration to control, but it has limited reach and obstacle-avoidance

capabilities, Fig. 1.6B.

Cartesian and Gantry. This robot comprises three orthogonal linear joints (Joints

1e3). Gantry robots are far more rigid than the basic Cartesian configuration; they

have considerable reach capabilities, and they require a minimum floor area for

the robot itself, Fig. 1.6C.

Jointed Arm. These robots consist of three joints (Joints 1e3) arranged in an

anthropomorphic configuration. This is the most widely used configuration in gen-

eral manufacturing applications, Fig. 1.6D.

Selective-compliance-assembly robotic arm. A SCARA robot consists of two rotary

axes (Joints 1e2) and a linear joint (Joint 3). The arm is very rigid in the vertical

direction but is compliant in the horizontal direction. These attributes make it

suitable for certain assembly tasks, in particular printed circuit boards, Fig. 1.6E.

A conventional robotic manipulator has three joints; this allows the tool at the end of

the arm to be positioned anywhere in the robot’s working envelope. To orientate the

tools, three additional joints are required; these are normally mounted at the end of the

arm in a wrist assembly. One design approach to a wrist is shown in Fig. 1.6F, it must be

noted that the design of the wrist can have a significant impact on the manipulator’s