Page 39 - Electrical Equipment Handbook _ Troubleshooting and Maintenance

P. 39

INTRODUCTION TO MACHINERY PRINCIPLES

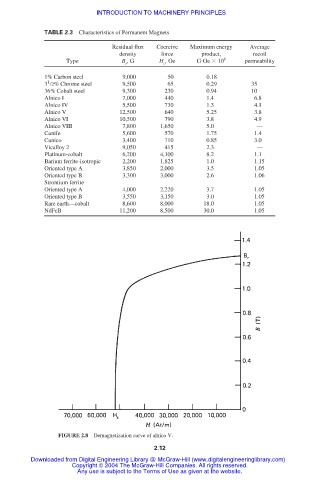

TABLE 2.3 Characteristics of Permanent Magnets

Residual flux Coercive Maximum energy Average

density force product, recoil

Type B , G H , Oe G Oe 10 6 permeability

r

c

1% Carbon steel 9,000 50 0.18

1

3 2% Chrome steel 9,500 65 0.29 35

36% Cobalt steel 9,300 230 0.94 10

Alnico I 7,000 440 1.4 6.8

Alnico IV 5,500 730 1.3 4.1

Alnico V 12,500 640 5.25 3.8

Alnico VI 10,500 790 3.8 4.9

Alnico VIII 7,800 1,650 5.0 —

Cunife 5,600 570 1.75 1.4

Cunico 3,400 710 0.85 3.0

Vicalloy 2 9,050 415 2.3 —

Platinum-cobalt 6,200 4,100 8.2 1.1

Barium ferrite-isotropic 2,200 1,825 1.0 1.15

Oriented type A 3,850 2,000 3.5 1.05

Oriented type B 3,300 3,000 2.6 1.06

Strontium ferrite

Oriented type A 4,000 2,220 3.7 1.05

Oriented type B 3,550 3,150 3.0 1.05

Rare earth—cobalt 8,600 8,000 18.0 1.05

NdFeB 11,200 8,500 30.0 1.05

FIGURE 2.8 Demagnetization curve of alnico V.

2.12

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com)

Copyright © 2004 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.