Page 89 - Electrical Equipment Handbook _ Troubleshooting and Maintenance

P. 89

TRANSFORMER COMPONENTS AND MAINTENANCE

4.18 CHAPTER FOUR

will have a high neutralization number. An excellent indicator of the oil condition is

obtained by dividing the IFT by the NN. This ratio is known as the Myers index number

(MIN) or oil quality index number. For example, the MIN for a new oil is around 1500:

IFT

MIN

NN

45.0 (typical new oil)

1500

0.03 (typical new oil)

The Transformer Oil Classification System

The seven classifications of the transformer oil are presented in Table 4.3. They are based

on the oil’s ability to perform its four intended functions (cooling, insulation, protection

against chemical attack, and prevention of sludge buildup).

The oil in category 1 can perform efficiently all four functions. It does not require atten-

tion other than periodic testing.

Preventive maintenance is required for the oils in categories 2 and 3. The decrease of

IFT to 27.0 indicates the start of sludge in solution. At this stage, the oil is less than ideal,

but does not require immediate attention.

Oil in category 3 (marginal) is not providing adequate cooling and winding protection.

At this stage, fatty acids have begun to coat the winding insulation. The sludge has also

begun to build up in the insulation voids. Numerous studies of transformer failures for oils

in categories 2 and 3 revealed sludge in the voids of the insulation system. This is the rea-

son for not deferring transformer maintenance when they contain marginal oil.

Transformers containing oils in categories 4, 5, and 6 should be serviced promptly.

Sludge has already been deposited on most of the winding and core in category 4.

Considerable insulation shrinkage and blockage of cooling vents would have occurred in

categories 5 and 6 (extremely bad) due to oil deterioration. The transformer should be

replaced if the oil is found in category 7.

There is some overlap of MIN ranges in the first three categories. This overlap is due to

the fact that the oil should meet the criteria for both minimum IFT and maximum NN for

the category, in addition to falling within the range given for MIN.

Table 4.4 summarizes the results of a study on 500 transformers to determine the rela-

tionship between IFT, NN, and the sludge content. The transformers have been selected

from different industrial environments. All 500 transformers experienced visible sludge

buildup when the NN exceeded 0.6 mg KOH/g, or IFT dropped below 14.0 dyn/cm.

Figure 4.12 illustrates the relationship between NN, IFT, and the condition of trans-

former oil. If a sickeningly sweet odor is detected while the oil sample is taken, additional

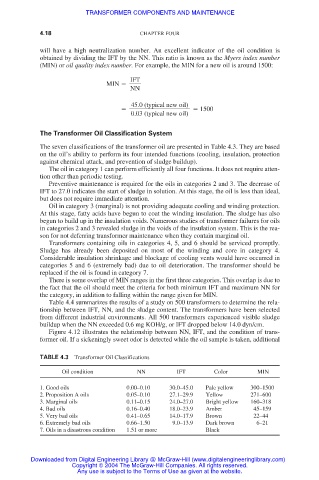

TABLE 4.3 Transformer Oil Classifications

Oil condition NN IFT Color MIN

1. Good oils 0.00–0.10 30.0–45.0 Pale yellow 300–1500

2. Proposition A oils 0.05–0.10 27.1–29.9 Yellow 271–600

3. Marginal oils 0.11–0.15 24.0–27.0 Bright yellow 160–318

4. Bad oils 0.16–0.40 18.0–23.9 Amber 45–159

5. Very bad oils 0.41–0.65 14.0–17.9 Brown 22–44

6. Extremely bad oils 0.66–1.50 9.0–13.9 Dark brown 6–21

7. Oils in a disastrous condition 1.51 or more Black

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com)

Copyright © 2004 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.