Page 94 - Electrical Equipment Handbook _ Troubleshooting and Maintenance

P. 94

TRANSFORMER COMPONENTS AND MAINTENANCE

TRANSFORMER COMPONENTS AND MAINTENANCE 4.23

TOUGH

CAST ALUMINUM

BODY

GAS

BLEEDER VALVE ACCUMULATION

Small to prevent CHAMBER MAGNETIC

wave shock tripping Gas build up INDICATOR

does not affect

of pressure switch operation of bellows

TILT-PROOF

BUTTON-TYPE

FLOAT MICROSWITCH

ALARM

LEADS

JOINT

Lower unit may

be used alone as

pressure

fault relay

BELLOWS PRESSURE

Seals out oil EQUALIZING

Compresses air to BUTTON SILICONE

flex diaphragm TYPE RUBBER

MICRO DIAPHRAGM

SWITCH AND SEAL

From transformer OIL AIR VENT

and gas collection INLET

system WATERPROOF

DIAPHRAGM PLUG

GAS AND OIL Actuates CONNECTOR

PRESSURE PRESSURE switch

TEST CONNECTION CHAMBER

BYPASS

3 EASY ATTACH

MOUNTING LUGS

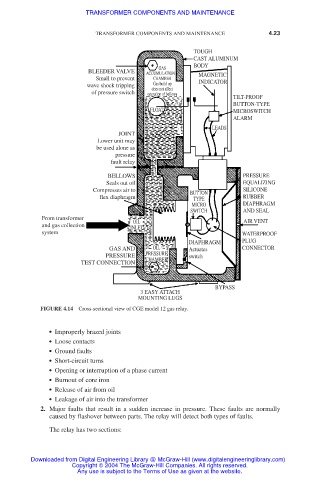

FIGURE 4.14 Cross-sectional view of CGE model 12 gas relay.

● Improperly brazed joints

● Loose contacts

● Ground faults

● Short-circuit turns

● Opening or interruption of a phase current

● Burnout of core iron

● Release of air from oil

● Leakage of air into the transformer

2. Major faults that result in a sudden increase in pressure. These faults are normally

caused by flashover between parts. The relay will detect both types of faults.

The relay has two sections:

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com)

Copyright © 2004 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.