Page 181 - Electrical Installation in Hazardous Area

P. 181

Area classification in areas which are not freely ventilated 147

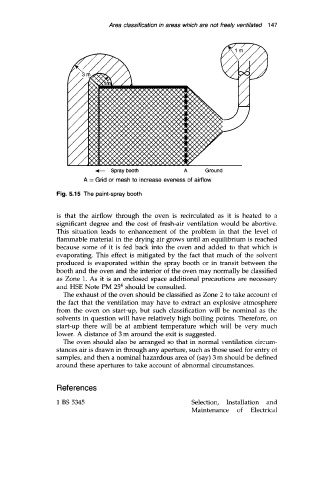

t Spray booth A Ground

A = Grid or mesh to increase eveness of airflow

Fig. 5.15 The paint-spray booth

is that the airflow through the oven is recirculated as it is heated to a

significant degree and the cost of fresh-air ventilation would be abortive.

This situation leads to enhancement of the problem in that the level of

flammable material in the drying air grows until an equilibrium is reached

because some of it is fed back into the oven and added to that which is

evaporating. This effect is mitigated by the fact that much of the solvent

produced is evaporated within the spray booth or in transit between the

booth and the oven and the interior of the oven may normally be classified

as Zone 1. As it is an enclosed space additional precautions are necessary

and HSE Note I'M 254 should be consulted.

The exhaust of the oven should be classified as Zone 2 to take account of

the fact that the ventilation may have to extract an explosive atmosphere

from the oven on start-up, but such classification will be nominal as the

solvents in question will have relatively high boiling points. Therefore, on

start-up there will be at ambient temperature which will be very much

lower. A distance of 3m around the exit is suggested.

The oven should also be arranged so that in normal ventilation circum-

stances air is drawn in through any aperture, such as those used for entry of

samples, and then a nominal hazardous area of (say) 3 m should be defined

around these apertures to take account of abnormal circumstances.

References

1 BS 5345 Selection, Installation and

Maintenance of Electrical