Page 49 - Elements of Chemical Reaction Engineering Ebook

P. 49

20 Mole Balances Chap. 1

The feed consists of 3 to 7% HNO,, 59 to 67% H,SO,, and 28 to 37% water. Sul-

furic acid is necessary to adsorb the water and energy generated by the heat of reac-

tion. The plant, which produces 15,000 lb nitrobenzenelh, requires one or two

operators per shift together with a plant supervisor and part-time foreman. This exo-

thermic reaction is carried out essentially adiabatically, so that the temperature of

the feed stream rises from 90°C to 135°C at the exit. One observes that the nitroben-

zene stream from the separator is used to heat the benzene feed. However, care must

be taken so that the temperature never exceeds 19O0C, where secondary reactions

could result in an explosion. One of the safety precautions is the installation of relief

valves that will rupture before the temperature approaches 1 9O"C, thereby allowing

a boil-off of water and benzene, which would drop the reactor temperature.

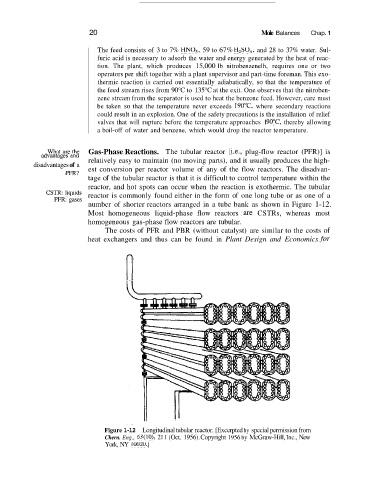

What are the Gas-Phase Reactions. The tubular reactor [Le., plug-flow reactor (PFR)] is

advantages and relatively easy to maintain (no moving parts), and it usually produces the high-

disadvantages of a

pm? est conversion per reactor volume of any of the flow reactors. The disadvan-

tage of the tubular reactor is that it is difficult to control temperature within the

reactor, and hot spots can occur when the reaction is exothermic. The tubular

CSTR: liquids reactor is commonly found either in the form of one long tube or as one of a

PFR: gases

number of shorter reactors arranged in a tube bank as shown in Figure 1-12.

Most homogeneous liquid-phase flow reactors are CSTRs, whereas most

homogeneous gas-phase flow reactors are tubular.

The costs of PFR and PBR (without catalyst) are similar to the costs of

heat exchangers and thus can be found in Plant Design and Economics for

n

Figure 1-12 Longitudinal tubular reactor. [Excerpted by special permission from

Chern. Eng., 63(10), 21 1 (Oct. 1956). Copyright 1956 by McGraw-Hill, Inc., New

York, NY 10020.]