Page 53 - Elements of Chemical Reaction Engineering Ebook

P. 53

~

24 Mole Balances Chap. 1

before the stream is recycled include Synoil (a synthetic crude), water, methyl ethyl

ketone (MEK), alcohols, acids, and aldehydes. The reactor is operated at 25 atm and

350°C and at any one time contains 150 tons of catalyst. The catalyst feed rate is 6

to 9.5 tons/s, and the gas recycle ratio is 2: 1.

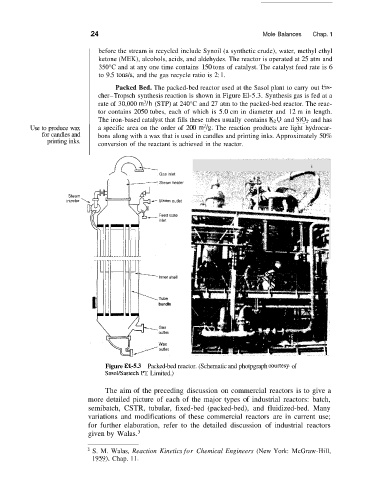

Packed Bed. The packed-bed reactor used at the Sasol plant to carry out Fis-

cher-Tropsch synthesis reaction is shown in Figure El-5.3. Synthesis gas is fed at a

rate of 30,000 m3/h (STP) at 240°C and 27 atm to the packed-bed reactor. The reac-

tor contains 2050 tubes, each of which is 5.0 cm in diameter and 12 m in length.

The iron-based catalyst that fills these tubes usually contains K,O and SiO, and has

Use to produce wax a specific area on the order of 200 m2/g. The reaction products are light hydrocar-

for candles and bons along with a wax that is used in candles and printing inks. Approximately 50%

printing inks. conversion of the reactant is achieved in the reactor.

s J

( 1- Gas inlet

Steam heater

Steam

iniector -Steam outlet

bundle

Figure a-5.3 Packed-bed reactor. (Schematic and photpgraph dourtesy of

Sasol/Sastech W Limited.)

The aim of the preceding discussion on commercial reactors is to give a

more detailed picture of each of the major types of industrial reactors: batch,

semibatch, CSTR, tubular, fixed-bed (packed-bed), and fluidized-bed. Many

variations and modifications of these commercial reactors are in current use;

for further elaboration, refer to the detailed discussion of industrial reactors

given by Walas.

S. M. Walas, Reaction Kinetics for Chemical Engineers (New York: McGraw-Hill,

1959), Chap. 1 1.