Page 555 - Elements of Chemical Reaction Engineering Ebook

P. 555

Chap. (3 Questions and Problems 525

Additional information:

cal

k, = 0.4

cm . min . K .

Reactor diameter = 3 cm

Plat temperature reaction rate as a function of radius at specific locations

down the reactor. Plot the centerline temperature as a function of conversion.

(8) What do you think about neglecting radial variations in concentration?

Read Chapter 11, then show that

m

a2T k 3T

a2T

dT

k,--fk,-+~---~ 2 CC -

3zz ar2 r ar pJ az

where De is the effective diffusivity. (Experts only)

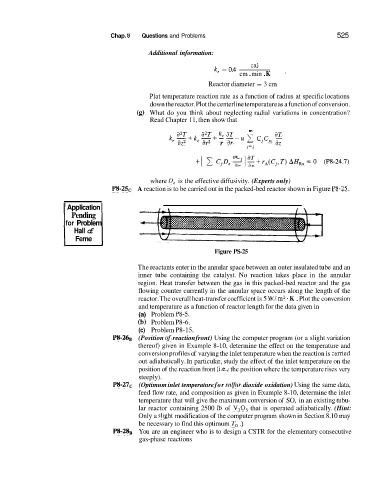

P8-2SC A reaction is to be carried out in the packed-bed reactor shown in Figure P8-25.

I Feme 1

Application

Pending

for Problem

Hall of

Figure PS-25

The reactants enter in the annular space between an outer insulated tube and an

inner tube containing the catalyst. No reaction takes place in the annular

region. Heat transfer between the gas in this packed-bed reactor and the gas

flowing counter currently in the annular space occurs along the length of the

reactor. The overall heat-transfer coefficient is 5 W/ m2 K . Plot the conversion

and temperature as a function of reactor length for the data given in

(a) Problem P8-5.

(b) Problem P8-6.

(c) Problem P8-15.

3?8-26B (Position of reaction front) Using the computer program (or a slight variation

thereof) given in Example 8-10, determine the effect on the temperature and

conversion profiles of varying the inlet temperature when the reaction is c'anied

out adiabatically. In particular, study the effect of the inlet temperature on the

position of the reaction front (i.e., the position where the temperature rises very

steeply).

PS-27, (Optimum inlet temperature for sulfur dioxide oxidation) Using the same data,

feed flow rate, and composition as given in Example 8-10, determine the inlet

temperature that will give the maximum conversion of SO, in an existing tubu-

lar reactor containing 2500 Ib of V20, that is operated adiabatically. (Hint:

Only a slight modification of the computer program shown in Section 8.10 may

be necessary to find this optimum To .)

P8-2SB You are an engineer who is to design a CSTR for the elementary consecutive

gas-phase reactions