Page 386 - Academic Press Encyclopedia of Physical Science and Technology 3rd Chemical Engineering

P. 386

P1: GLQ Final Pages

Encyclopedia of Physical Science and Technology EN009K-419 July 19, 2001 20:57

Membranes, Synthetic, Applications 321

FIGURE 33 An ultrahigh-purity water system for semiconductor manufacture. (Nitto Electric Industrial Co., Ltd.)

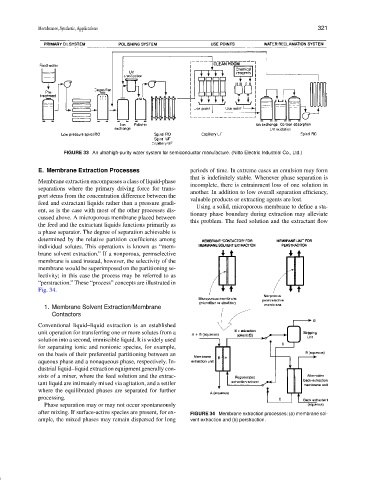

E. Membrane Extraction Processes periods of time. In extreme cases an emulsion may form

that is indefinitely stable. Whenever phase separation is

Membrane extraction encompasses a class of liquid-phase

incomplete, there is entrainment loss of one solution in

separations where the primary driving force for trans-

another. In addition to low overall separation efficiency,

port stems from the concentration difference between the

valuable products or extracting agents are lost.

feed and extractant liquids rather than a pressure gradi-

Using a solid, microporous membrane to define a sta-

ent, as is the case with most of the other processes dis-

tionary phase boundary during extraction may alleviate

cussed above. A microporous membrane placed between

this problem. The feed solution and the extractant flow

the feed and the extractant liquids functions primarily as

a phase separator. The degree of separation achievable is

determined by the relative partition coefficients among

individual solutes. This operationx is known as “mem-

brane solvent extraction.” If a nonporous, permselective

membrane is used instead, however, the selectivity of the

membrane would be superimposed on the partitioning se-

lectivity; in this case the process may be referred to as

“perstraction.” These “process” concepts are illustrated in

Fig. 34.

1. Membrane Solvent Extraction/Membrane

Contactors

Conventional liquid–liquid extraction is an established

unit operation for transferring one or more solutes from a

solution into a second, immiscible liquid. It is widely used

for separating ionic and nonionic species, for example,

on the basis of their preferential partitioning between an

aqueous phase and a nonaqueous phase, respectively. In-

dustrial liquid–liquid extraction equipment generally con-

sists of a mixer, where the feed solution and the extrac-

tant liquid are intimately mixed via agitation, and a settler

where the equilibrated phases are separated for further

processing.

Phase separation may or may not occur spontaneously

after mixing. If surface-active species are present, for ex- FIGURE 34 Membrane extraction processes: (a) membrane sol-

ample, the mixed phases may remain dispersed for long vent extraction and (b) perstraction.