Page 384 - Academic Press Encyclopedia of Physical Science and Technology 3rd Chemical Engineering

P. 384

P1: GLQ Final Pages

Encyclopedia of Physical Science and Technology EN009K-419 July 19, 2001 20:57

Membranes, Synthetic, Applications 319

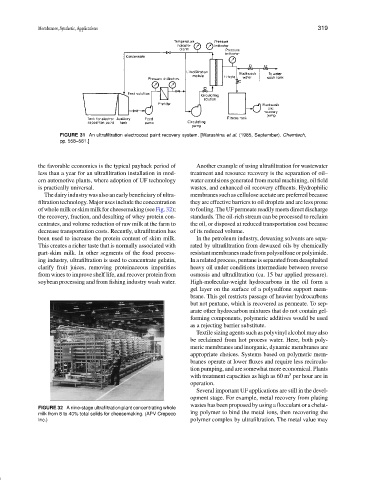

FIGURE 31 An ultrafiltration electrocoat paint recovery system. [Warashina et al. (1985, September). Chemtech,

pp. 558–561.]

the favorable economics is the typical payback period of Another example of using ultrafiltration for wastewater

less than a year for an ultrafiltration installation in mod- treatment and resource recovery is the separation of oil–

ern automotive plants, where adoption of UF technology water emulsions generated from metal machining, oil field

is practically universal. wastes, and enhanced oil recovery effluents. Hydrophilic

The dairy industry was also an early beneficiary of ultra- membranes such as cellulose acetate are preferred because

filtration technology. Major uses include the concentration they are effective barriers to oil droplets and are less prone

ofwholemilkorskimmilkforcheesemaking(seeFig.32); tofouling.TheUFpermeatereadilymeetsdirectdischarge

the recovery, fraction, and desalting of whey protein con- standards. The oil-rich stream can be processed to reclaim

centrates, and volume reduction of raw milk at the farm to the oil, or disposed at reduced transportation cost because

decrease transportation costs. Recently, ultrafiltration has of its reduced volume.

been used to increase the protein content of skim milk. In the petroleum industry, dewaxing solvents are sepa-

This creates a richer taste that is normally associated with rated by ultrafiltration from dewaxed oils by chemically

part-skim milk. In other segments of the food process- resistantmembranesmadefrompolysulfoneorpolyimide.

ing industry, ultrafiltration is used to concentrate gelatin, In a related process, pentane is separated from deasphalted

clarify fruit juices, removing proteinaceous impurities heavy oil under conditions intermediate between reverse

from wines to improve shelf life, and recover protein from osmosis and ultrafiltration (ca. 15 bar applied pressure).

soybean processing and from fishing industry wash water. High-molecular-weight hydrocarbons in the oil form a

gel layer on the surface of a polysulfone support mem-

brane. This gel restricts passage of heavier hydrocarbons

but not pentane, which is recovered as permeate. To sep-

arate other hydrocarbon mixtures that do not contain gel-

forming components, polymeric additives would be used

as a rejecting barrier substitute.

Textile sizing agents such as polyvinyl alcohol may also

be reclaimed from hot process water. Here, both poly-

meric membranes and inorganic, dynamic membranes are

appropriate choices. Systems based on polymeric mem-

branes operate at lower fluxes and require less recircula-

tion pumping, and are somewhat more economical. Plants

3

with treatment capacities as high as 60 m per hour are in

operation.

Several important UF applications are still in the devel-

opment stage. For example, metal recovery from plating

wastes has been proposed by using a flocculant or a chelat-

FIGURE 32 A nine-stage ultrafiltration plant concentrating whole

ing polymer to bind the metal ions, then recovering the

milk from 8 to 40% total solids for cheesemaking. (APV Crepeco

Inc.) polymer complex by ultrafiltration. The metal value may