Page 388 - Academic Press Encyclopedia of Physical Science and Technology 3rd Chemical Engineering

P. 388

P1: GLQ Final Pages

Encyclopedia of Physical Science and Technology EN009K-419 July 19, 2001 20:57

Membranes, Synthetic, Applications 323

the target substances. The emulsion is coalesced chemi-

cally or electrostatically to release the encapsulated liquid

and to recycle the liquid membrane constituents.

2. Immobilized Liquid Membranes

An immobilized liquid membrane is formed by impreg-

nating a microporous support with an extractant liquid.

The liquid is held in place by capillarity and assumes the

flat-sheet or hollow-fiber geometry of the host membrane.

Immobilized liquid membranes can be used for virtually

all the liquid-phase separations achievable with emulsified

liquid membranes, but offer several important benefits.

There should be no entrainment loss because no mixing

occurs. Also, extraction and stripping of target species oc-

cur simultaneously on the upstream and downstream sur-

faces of an immobilized liquid membrane, respectively.

The size of the receiving phase can thus be virtually un-

limitedbycontinuallyregeneratingandrecyclingthestrip-

ping solution. Hollow-fiber devices may be used to favor

a high packing density of contact area between the im-

miscible phases. Finally, because it is supported in a solid

matrix, an immobilized liquid membrane is applicable to

the separation of gases and vapors.

3. Facilitated Transport and Coupled Transport

It is possible to achieve very high selectivities by incorpo-

rating complexing agents or carriers in immobilized liquid

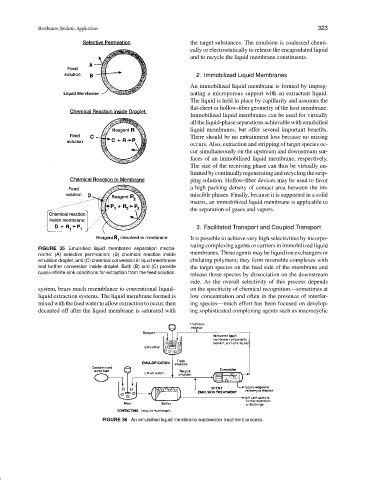

FIGURE 35 Emulsified liquid membrane separation mecha-

membranes. These agents may be liquid ion exchangers or

nisms: (A) selective permeation; (B) chemical reaction inside

emulsion droplet; and (C) chemical conversion in liquid membrane chelating polymers; they form reversible complexes with

and further conversion inside droplet. Both (B) and (C) provide the target species on the feed side of the membrane and

quasi-infinite sink conditions for extraction from the feed solution.

release those species by dissociation on the downstream

side. As the overall selectivity of this process depends

system, bears much resemblance to conventional liquid– on the specificity of chemical recognition—sometimes at

liquid extraction systems. The liquid membrane formed is low concentration and often in the presence of interfer-

mixedwiththefeedwatertoallowextractiontooccur,then ing species—much effort has been focused on develop-

decanted off after the liquid membrane is saturated with ing sophisticated complexing agents such as macrocyclic

FIGURE 36 An emulsified liquid membrane wastewater treatment process.