Page 82 - Academic Press Encyclopedia of Physical Science and Technology 3rd Chemical Engineering

P. 82

P1: LLL Revised Pages

Encyclopedia of Physical Science and Technology EN002E-49 May 17, 2001 20:13

46 Batch Processing

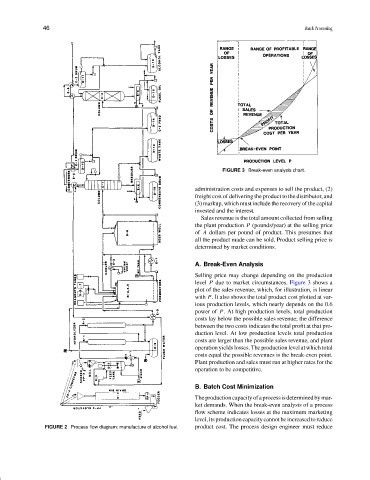

FIGURE 3 Break-even analysis chart.

administration costs and expenses to sell the product, (2)

freight cost of delivering the product to the distributor, and

(3) markup, which must include the recovery of the capital

invested and the interest.

Sales revenue is the total amount collected from selling

the plant production P (pounds/year) at the selling price

of A dollars per pound of product. This presumes that

all the product made can be sold. Product selling price is

determined by market conditions.

A. Break-Even Analysis

Selling price may change depending on the production

level P due to market circumstances. Figure 3 shows a

plot of the sales revenue, which, for illustration, is linear

with P. It also shows the total product cost plotted at var-

ious production levels, which nearly depends on the 0.6

power of P. At high production levels, total production

costs lay below the possible sales revenue; the difference

between the two costs indicates the total profit at that pro-

duction level. At low production levels total production

costs are larger than the possible sales revenue, and plant

operation yields losses. The production level at which total

costs equal the possible revenues is the break-even point.

Plant production and sales must run at higher rates for the

operation to be competitive.

B. Batch Cost Minimization

Theproductioncapacityofaprocessisdeterminedbymar-

ket demands. When the break-even analysis of a process

flow scheme indicates losses at the maximum marketing

level, its production capacity cannot be increased to reduce

FIGURE 2 Process flow diagram: manufacture of alcohol fuel. product cost. The process design engineer must reduce