Page 127 - Academic Press Encyclopedia of Physical Science and Technology 3rd Organic Chemistry

P. 127

P1: FPP Revised Pages

Encyclopedia of Physical Science and Technology EN002C-85 May 17, 2001 20:35

Catalysis, Homogeneous 475

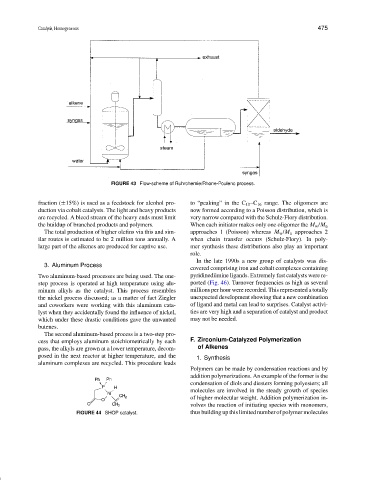

FIGURE 43 Flow-scheme of Ruhrchemie/Rhone-Poulenc process.

fraction (±15%) is used as a feedstock for alcohol pro- to “peaking” in the C 10 –C 16 range. The oligomers are

duction via cobalt catalysts. The light and heavy products now formed according to a Poisson distribution, which is

are recycled. A bleed stream of the heavy ends must limit very narrow compared with the Schulz-Flory distribution.

the buildup of branched products and polymers. When each initiator makes only one oligomer the M w /M n

The total production of higher olefins via this and sim- approaches 1 (Poisson) whereas M w /M n approaches 2

ilar routes is estimated to be 2 million tons annually. A when chain transfer occurs (Schulz-Flory). In poly-

large part of the alkenes are produced for captive use. mer synthesis these distributions also play an important

role.

In the late 1990s a new group of catalysts was dis-

3. Aluminum Process

covered comprising iron and cobalt complexes containing

Two aluminum-based processes are being used. The one- pyridinediimine ligands. Extremely fast catalysts were re-

step process is operated at high temperature using alu- ported (Fig. 46). Turnover frequencies as high as several

minum alkyls as the catalyst. This process resembles millions per hour were recorded. This represented a totally

the nickel process discussed; as a matter of fact Ziegler unexpected development showing that a new combination

and coworkers were working with this aluminum cata- of ligand and metal can lead to surprises. Catalyst activi-

lyst when they accidentally found the influence of nickel, ties are very high and a separation of catalyst and product

which under these drastic conditions gave the unwanted may not be needed.

butenes.

The second aluminum-based process is a two-step pro-

cess that employs aluminum stoichiometrically by each F. Zirconium-Catalyzed Polymerization

pass, the alkyls are grown at a lower temperature, decom- of Alkenes

posed in the next reactor at higher temperature, and the 1. Synthesis

aluminum complexes are recycled. This procedure leads

Polymers can be made by condensation reactions and by

addition polymerizations. An example of the former is the

condensation of diols and diesters forming polyesters; all

molecules are involved in the steady growth of species

of higher molecular weight. Addition polymerization in-

volves the reaction of initiating species with monomers,

FIGURE 44 SHOP catalyst. thus building up this limited number of polymer molecules