Page 101 - Energy from Toxic Organic Waste for Heat and Power Generation

P. 101

86 Energy from Toxic Organic Waste for Heat and Power Generation

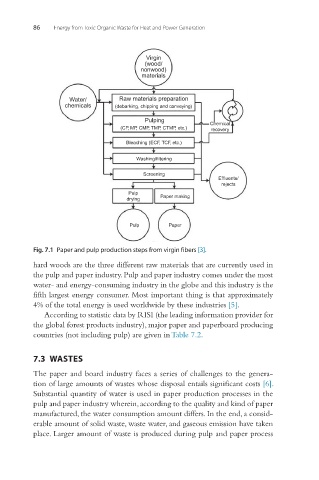

Virgin

(wood/

nonwood)

materials

Water/ Raw materials preparation

chemicals (debarking, chipping and conveying)

Pulping Chemical

(CP, MP, CMP, TMP, CTMP, etc.) recovery

Bleaching (ECF, TCF, etc.)

Washing/filtering

Screening

Effluents/

rejects

Pulp

drying Paper making

Pulp Paper

Fig. 7.1 Paper and pulp production steps from virgin fibers [3].

hard woods are the three different raw materials that are currently used in

the pulp and paper industry. Pulp and paper industry comes under the most

water- and energy-consuming industry in the globe and this industry is the

fifth largest energy consumer. Most important thing is that approximately

4% of the total energy is used worldwide by these industries [5].

According to statistic data by RISI (the leading information provider for

the global forest products industry), major paper and paperboard producing

countries (not including pulp) are given in Table 7.2.

7.3 WASTES

The paper and board industry faces a series of challenges to the genera-

tion of large amounts of wastes whose disposal entails significant costs [6].

Substantial quantity of water is used in paper production processes in the

pulp and paper industry wherein, according to the quality and kind of paper

manufactured, the water consumption amount differs. In the end, a consid-

erable amount of solid waste, waste water, and gaseous emission have taken

place. Larger amount of waste is produced during pulp and paper process