Page 78 - Energy from Toxic Organic Waste for Heat and Power Generation

P. 78

64 Energy from Toxic Organic Waste for Heat and Power Generation

Organic polymers

Fats, proteins, poly-saccharides

Hydrolysis Fermentative NH , S 2–

+

micro-organisms 4

4% 76% 20%

Alcohols,

+

C carboxylic acids

3

Acetogenesis

24% 52%

Acetogens

H , CO 2 Acetate

2

Homoacetogenesis

Hydrogenophilic 72% Acetophilic

Methanogenesis methanogens 28% methanogens

CH 4 , CO 2

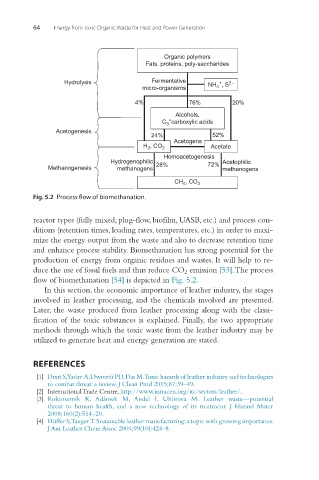

Fig. 5.2 Process flow of biomethanation.

reactor types (fully mixed, plug-flow, biofilm, UASB, etc.) and process con-

ditions (retention times, loading rates, temperatures, etc.) in order to maxi-

mize the energy output from the waste and also to decrease retention time

and enhance process stability. Biomethanation has strong potential for the

production of energy from organic residues and wastes. It will help to re-

duce the use of fossil fuels and thus reduce CO 2 emission [53]. The process

flow of biomethanation [54] is depicted in Fig. 5.2.

In this section, the economic importance of leather industry, the stages

involved in leather processing, and the chemicals involved are presented.

Later, the waste produced from leather processing along with the classi-

fication of the toxic substances is explained. Finally, the two appropriate

methods through which the toxic waste from the leather industry may be

utilized to generate heat and energy generation are stated.

REFERENCES

[1] Dixit S, Yadav A, Dwivedi PD, Das M. Toxic hazards of leather industry and technologies

to combat threat: a review. J Clean Prod 2015;87:39–49.

[2] International Trade Centre, http://www.intracen.org/itc/sectors/leather/.

[3] Kolomazník K, Adámek M, Andel I, Uhlirova M. Leather waste—potential

threat to human health, and a new technology of its treatment. J Hazard Mater

2008;160(2):514–20.

[4] Hüffer S, Taeger T. Sustainable leather manufacturing: a topic with growing importance.

J Am Leather Chem Assoc 2004;99(10):424–8.