Page 316 - Engineered Interfaces in Fiber Reinforced Composites

P. 316

Chapter I. Improvement of transverse fracture toughness with interface control 291

variation functions were also considered to represent the Young’s modulus and the

CTE of the interphase (Jayaraman and Reifsnider, 1993).

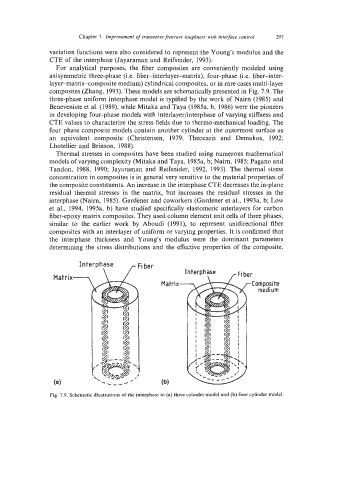

For analytical purposes, the fiber composites are conveniently modeled using

axisymmetric three-phase (i.e. fiber-interlayer-matrix), four-phase (i.e. fiber-inter-

layer-matrix-composite medium) cylindrical composites, or in rare cases multi-layer

composites (Zhang, 1993). These models are schematically presented in Fig. 7.9. The

three-phase uniform interphase model is typified by the work of Nairn (1985) and

Beneveniste et al. (1989), while Mitaka and Taya (1985a, b, 1986) were the pioneers

in developing four-phase models with interlayer/interphase of varying stiffness and

CTE values to characterize the stress fields due to thermo-mechanical loading. The

four phase composite models contain another cylinder at the outermost surface as

an equivalent composite (Christensen, 1979; Theocaris and Demakos, 1992;

Lhotellier and Brinson, 1988).

Thermal stresses in composites have been studied using numerous mathematical

models of varying complexity (Mitaka and Taya, 1985a, b; Nairn, 1985; Pagano and

Tandon, 1988, 1990; Jayaraman and Reifsnider, 1992, 1993). The thermal stress

concentration in composites is in general very sensitive to the material properties of

the composite constituents. An increase in the interphase CTE decreases the in-plane

residual thermal stresses in the matrix, but increases the residual stresses in the

interphase (Nairn, 1985). Gardener and coworkers (Gardener et al., 1993a, b; Low

et al., 1994, 1995a, b) have studied specifically elastomeric interlayers for carbon

fiber-epoxy matrix composites. They used column element unit cells of three phases,

similar to the earlier work by Aboudi (1991), to represent unidirectional fiber

composites with an interlayer of uniform or varying properties. It is confirmed that

the interphase thickness and Young’s modulus were the dominant parameters

determining the stress distributions and the effective properties of the composite,

Interphase Fi ber

medium

Fig. 7.9. Schematic illustrations of the interphase in (a) three cylinder model and (b) four cylinder model.