Page 145 - Engineering Plastics Handbook

P. 145

118 Engineering Plastics

TABLE 6.8 Properties of Foaming Agents*

HFC-245fa R-11 HCFC-141b Cyclopentane

Molecular weight 134.0 137.4 116.9 70.0

Boiling point, °C 15.3 23.8 32.2 49.3

Specific gravity, g/cc at 20°C 1.32 1.49 1.24 0.74

Vapor pressure, kPa at 20°C 122 88.0 69.0 34.0

Vapor thermal conductivity, 0.012 0.008 0.010 0.011

kcal/mh°C at 44°C

Flame limit, vol% None None 7.6–17.7 1.4–9.4

Ignition point, °C None None None −37

Lift time in atmosphere, yr 8.4 50 9.4 A few days

GWP (R-11 = 1) 0.21 1.0 0.12 <0.001

*Utech 96 Paper 55, p. 355.

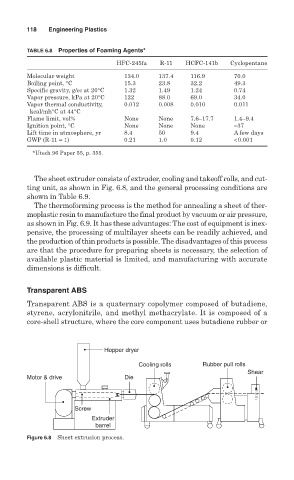

The sheet extruder consists of extruder, cooling and takeoff rolls, and cut-

ting unit, as shown in Fig. 6.8, and the general processing conditions are

shown in Table 6.9.

The thermoforming process is the method for annealing a sheet of ther-

moplastic resin to manufacture the final product by vacuum or air pressure,

as shown in Fig. 6.9. It has these advantages: The cost of equipment is inex-

pensive, the processing of multilayer sheets can be readily achieved, and

the production of thin products is possible. The disadvantages of this process

are that the procedure for preparing sheets is necessary, the selection of

available plastic material is limited, and manufacturing with accurate

dimensions is difficult.

Transparent ABS

Transparent ABS is a quaternary copolymer composed of butadiene,

styrene, acrylonitrile, and methyl methacrylate. It is composed of a

core-shell structure, where the core component uses butadiene rubber or

Hopper dryer

Cooling rolls Rubber pull rolls

Shear

Motor & drive Die

Screw

Extruder

barrel

Figure 6.8 Sheet extrusion process.