Page 174 - Engineering Plastics Handbook

P. 174

Polybutylene Terephthalate (PBT) 147

2.5

PBT

Total shrinkage (neat)

Mold shrinkage (%) 1.5 Mold shrinkage

2.0

1.0

PBT

(GF 30%)

0.5

Postshrinkage

(120°C, 12 h)

0.0

30 50 70 90 110 130

Mold temperature (°C)

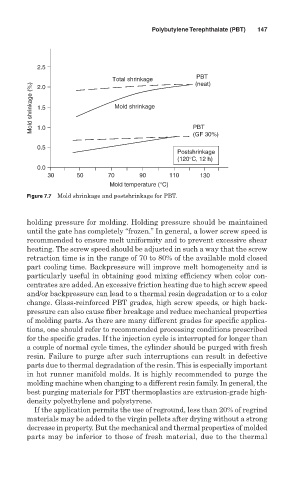

Figure 7.7 Mold shrinkage and postshrinkage for PBT.

holding pressure for molding. Holding pressure should be maintained

until the gate has completely “frozen.” In general, a lower screw speed is

recommended to ensure melt uniformity and to prevent excessive shear

heating. The screw speed should be adjusted in such a way that the screw

retraction time is in the range of 70 to 80% of the available mold closed

part cooling time. Backpressure will improve melt homogeneity and is

particularly useful in obtaining good mixing efficiency when color con-

centrates are added. An excessive friction heating due to high screw speed

and/or backpressure can lead to a thermal resin degradation or to a color

change. Glass-reinforced PBT grades, high screw speeds, or high back-

pressure can also cause fiber breakage and reduce mechanical properties

of molding parts. As there are many different grades for specific applica-

tions, one should refer to recommended processing conditions prescribed

for the specific grades. If the injection cycle is interrupted for longer than

a couple of normal cycle times, the cylinder should be purged with fresh

resin. Failure to purge after such interruptions can result in defective

parts due to thermal degradation of the resin. This is especially important

in hot runner manifold molds. It is highly recommended to purge the

molding machine when changing to a different resin family. In general, the

best purging materials for PBT thermoplastics are extrusion-grade high-

density polyethylene and polystyrene.

If the application permits the use of reground, less than 20% of regrind

materials may be added to the virgin pellets after drying without a strong

decrease in property. But the mechanical and thermal properties of molded

parts may be inferior to those of fresh material, due to the thermal