Page 176 - Engineering Plastics Handbook

P. 176

Polybutylene Terephthalate (PBT) 149

14

12 Feed zone

10

Flight depth (mm) 8 Metering zone

6

4

2

0

30 50 70 90 110 130

Screw diameter (mm)

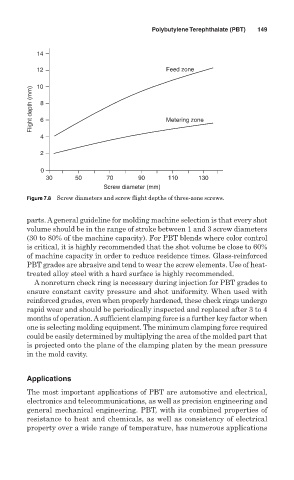

Figure 7.8 Screw diameters and screw flight depths of three-zone screws.

parts. Ageneral guideline for molding machine selection is that every shot

volume should be in the range of stroke between 1 and 3 screw diameters

(30 to 80% of the machine capacity). For PBT blends where color control

is critical, it is highly recommended that the shot volume be close to 60%

of machine capacity in order to reduce residence times. Glass-reinforced

PBT grades are abrasive and tend to wear the screw elements. Use of heat-

treated alloy steel with a hard surface is highly recommended.

A nonreturn check ring is necessary during injection for PBT grades to

ensure constant cavity pressure and shot uniformity. When used with

reinforced grades, even when properly hardened, these check rings undergo

rapid wear and should be periodically inspected and replaced after 3 to 4

months of operation. Asufficient clamping force is a further key factor when

one is selecting molding equipment. The minimum clamping force required

could be easily determined by multiplying the area of the molded part that

is projected onto the plane of the clamping platen by the mean pressure

in the mold cavity.

Applications

The most important applications of PBT are automotive and electrical,

electronics and telecommunications, as well as precision engineering and

general mechanical engineering. PBT, with its combined properties of

resistance to heat and chemicals, as well as consistency of electrical

property over a wide range of temperature, has numerous applications