Page 203 - Engineering Plastics Handbook

P. 203

176 Engineering Plastics

2.0

BPADA-MPD PEI @ 0.8 mm

1.5 BPADA-MPD PEI @ 1.6 mm

Absorbance 1.0

0.5

0.0

420 520 620 720 820 920 1020

Wavelength

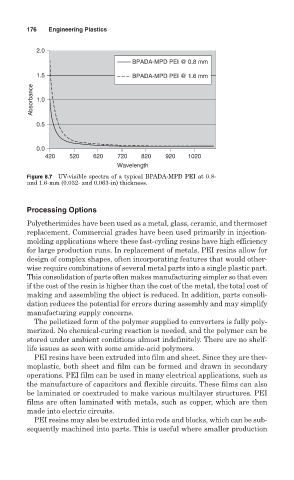

Figure 8.7 UV-visible spectra of a typical BPADA-MPD PEI at 0.8-

and 1.6-mm (0.032- and 0.063-in) thickness.

Processing Options

Polyetherimides have been used as a metal, glass, ceramic, and thermoset

replacement. Commercial grades have been used primarily in injection-

molding applications where these fast-cycling resins have high efficiency

for large production runs. In replacement of metals, PEI resins allow for

design of complex shapes, often incorporating features that would other-

wise require combinations of several metal parts into a single plastic part.

This consolidation of parts often makes manufacturing simpler so that even

if the cost of the resin is higher than the cost of the metal, the total cost of

making and assembling the object is reduced. In addition, parts consoli-

dation reduces the potential for errors during assembly and may simplify

manufacturing supply concerns.

The pelletized form of the polymer supplied to converters is fully poly-

merized. No chemical-curing reaction is needed, and the polymer can be

stored under ambient conditions almost indefinitely. There are no shelf-

life issues as seen with some amide-acid polymers.

PEI resins have been extruded into film and sheet. Since they are ther-

moplastic, both sheet and film can be formed and drawn in secondary

operations. PEI film can be used in many electrical applications, such as

the manufacture of capacitors and flexible circuits. These films can also

be laminated or coextruded to make various multilayer structures. PEI

films are often laminated with metals, such as copper, which are then

made into electric circuits.

PEI resins may also be extruded into rods and blocks, which can be sub-

sequently machined into parts. This is useful where smaller production