Page 231 - Engineering Plastics Handbook

P. 231

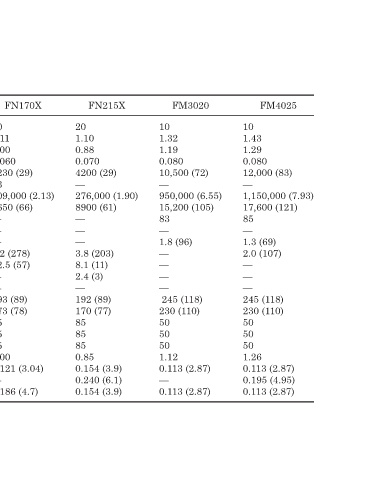

FM4025 12,000 (83) 1,150,000 (7.93) 17,600 (121) 245 (118) 230 (110) 0.113 (2.87) 0.195 (4.95) 0.113 (2.87)

10 1.43 1.29 0.080 — 85 — 1.3 (69) 2.0 (107) — — — 50 50 50 1.26

FM3020 10,500 (72) 950,000 (6.55) 15,200 (105) 245 (118) 230 (110) 0.113 (2.87) 0.113 (2.87)

10 1.32 1.19 0.080 — 83 — 1.8 (96) — — — — 50 50 50 1.12 —

FN215X 4200 (29) 276,000 (1.90) 8900 (61) 3.8 (203) 0.154 (3.9) 0.240 (6.1) 0.154 (3.9)

20 1.10 0.88 0.070 — — — — 8.1 (11) 2.4 (3) — 192 (89) 170 (77) 85 85 85 0.85

FN170X 4230 (29) 309,000 (2.13) 9650 (66) 5.2 (278) 42.5 (57) 0.121 (3.04) 0.186 (4.7)

10 1.11 1.12 1.00 0.90 0.060 0.060 4100 (28) 13 253,000 (1.74) 7600 (52) — — 121 — 6.4 (342) — — 230 (110) 193 (89) 193 (89) 173 (78) 165 (74) 85 85 85 1.00 0.90 — 0.156 (3.96) 0.156 (3.96)

FN150X

Properties of Structural Foam PPE/PS Grades Property 20 14 — — — Inst. impact E at peak, 73°F (23°C), ft⋅lb (J) — Inst. impact E at peak, −22°F (−30°C), in⋅lb (J) 50 50 RTI, mechanical properties with impact, °C 50 RTI, mechanical properties without impact, °C —

TABLE 9.7 Weight reduction Specific gravity, solid Specific gravity, foam-molded Water abs., 24 h at 73°F (23°C), % Tensile strength at yield, psi (MPa) Tensile elongation at break, % Flexural modulus, psi (GPa) Flexural strength, psi (MPa) Hardness, Rockwell M Hardness, Rockwell R NI at 73°F (23°

198