Page 234 - Engineering Plastics Handbook

P. 234

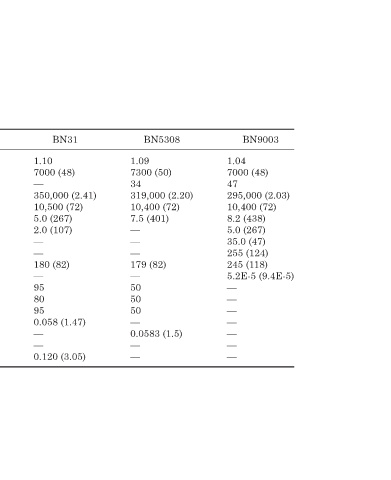

BN9003 7000 (48) 295,000 (2.03) 10,400 (72) 255 (124) 245 (118) 5.2E-5 (9.4E-5)

1.04 47 8.2 (438) 5.0 (267) 35.0 (47) — — — — — — —

BN5308 7300 (50) 319,000 (2.20) 10,400 (72) 7.5 (401) 0.0583 (1.5)

1.09 34 — — — 179 (82) — 50 50 50 — — —

BN31 7000 (48) 350,000 (2.41) 10,500 (72) 0.058 (1.47) 0.120 (3.05)

1.10 — 5.0 (267) 2.0 (107) — — 180 (82) — 95 80 95 — —

BN30 1.09 6200 (43) — 325,000 (2.24) 8600 (59) 5.0 (267) — — — 180 (82) — 50 50 50 — 0.125 (3.20) 0.062 (1.57) 0.150 (4.45)

Properties of PPE/PS Blow Molding-Grades Property Inst. impact E at peak, 73°F (23°C), ft⋅lb (J) CTE, flow −40 to 200°F, in/in-°F (m/m-°C)

TABLE 9.8 Specific gravity Tensile strength at yield, psi (MPa) Tensile elongation at break, % Flexural modulus, psi (GPa) Flexural strength, psi (MPa) NI at 23°C, ft⋅lb/in (J/m) NI at −40°F/°C, ft⋅lb/in (J/m) HDT at 66 psi (0.45 MPa), °F (°C) HDT at 264 psi (1.82 MPa), °F (°C) RTI electrical

200