Page 275 - Engineering Plastics Handbook

P. 275

Thermoplastic Polyimide (TPI) 237

200

Tensile strength, MPa 150

100

50

0

0 50 100 150 200 250 300 350

(122) (212) (302) (392) (482) (572) (662)

Temperature, °C (°F)

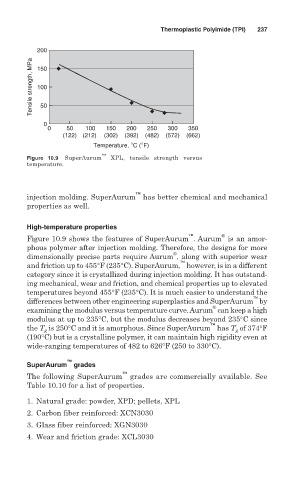

Figure 10.9 SuperAurum ™ XPL, tensile strength versus

temperature.

™

injection molding. SuperAurum has better chemical and mechanical

properties as well.

High-temperature properties

™ ®

Figure 10.9 shows the features of SuperAurum . Aurum is an amor-

phous polymer after injection molding. Therefore, the designs for more

®

dimensionally precise parts require Aurum , along with superior wear

™

and friction up to 455°F (235°C). SuperAurum, however, is in a different

category since it is crystallized during injection molding. It has outstand-

ing mechanical, wear and friction, and chemical properties up to elevated

temperatures beyond 455°F (235°C). It is much easier to understand the

™

differences between other engineering superplastics and SuperAurum by

®

examining the modulus versus temperature curve. Aurum can keep a high

modulus at up to 235°C, but the modulus decreases beyond 235°C since

™

the T is 250°C and it is amorphous. Since SuperAurum has T of 374°F

g

g

(190°C) but is a crystalline polymer, it can maintain high rigidity even at

wide-ranging temperatures of 482 to 626°F (250 to 330°C).

™

SuperAurum grades

™

The following SuperAurum grades are commercially available. See

Table 10.10 for a list of properties.

1. Natural grade: powder, XPD; pellets, XPL

2. Carbon fiber reinforced: XCN3030

3. Glass fiber reinforced: XGN3030

4. Wear and friction grade: XCL3030