Page 296 - Engineering Plastics Handbook

P. 296

256 Engineering Plastics

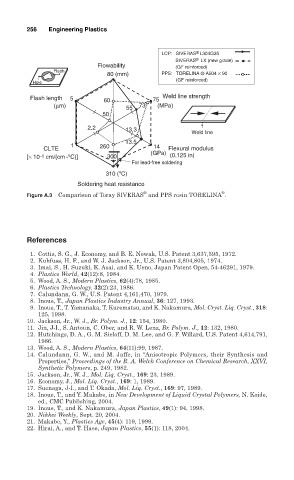

LCP: SIVERAS ® L304G35

SIVERAS ® LX (new grade)

Flowability (GF reinforced)

Flash

80 (mm) PPS: TORELINA ® A504 × 90

(GF reinforced)

Hole

Flash length 5 60 75 Weld line strength

(µm) 55 73 (MPa)

50

2.2 13.3

Weld line

13.5

1 260 14

CLTE Flexural modulus

(GPa)

–5

[× 10 cm/(cm ºC)] 300 (0.125 in)

For lead-free soldering

310 (ºC)

Soldering heat resistance

®

®

Figure A.3 Comparison of Toray SIVERAS and PPS resin TORELINA .

References

1. Cottis, S. G., J. Economy, and B. E. Nowak, U.S. Patent 3,637,595, 1972.

2. Kuhfuss, H. F., and W. J. Jackson, Jr., U.S. Patent 3,804,805, 1974.

3. Imai, S., H. Suzuki, K. Asai, and K. Ueno, Japan Patent Open, 54-46291, 1979.

4. Plastics World, 42(12):8, 1984.

5. Wood, A. S., Modern Plastics, 62(4):78, 1985.

6. Plastics Technology, 32(2):23, 1986.

7. Calundann, G. W., U.S. Patent 4,161,470, 1979.

8. Inoue, T., Japan Plastics Industry Annual, 36: 127, 1993.

9. Inoue, T., T. Yamanaka, T. Kurematsu, and K. Nakamura, Mol. Cryst. Liq. Cryst., 318:

125, 1998.

10. Jackson, Jr., W. J., Br. Polym. J., 12: 154, 1980.

11. Jin, J-I., S. Antoun, C. Ober, and R. W. Lenz, Br. Polym. J., 12: 132, 1980.

12. Hutchings, D. A., G. M. Sieloff, D. M. Lee, and G. F. Willard, U.S. Patent 4,614,791,

1986.

13. Wood, A. S., Modern Plastics, 64(11):99, 1987.

14. Calundann, G. W., and M. Jaffe, in “Anisotropic Polymers, their Synthesis and

Properties,” Proceedings of the R. A. Welch Conference on Chemical Research, XXVI,

Synthetic Polymers, p. 249, 1982.

15. Jackson, Jr., W. J., Mol. Liq. Cryst., 169: 23, 1989.

16. Economy, J., Mol. Liq. Cryst., 169: 1, 1989.

17. Suenaga, J-I., and T. Okada, Mol. Liq. Cryst., 169: 97, 1989.

18. Inoue, T., and Y. Makabe, in New Development of Liquid Crystal Polymers, N. Koide,

ed., CMC Publishing, 2004.

19. Inoue, T., and K. Nakamura, Japan Plastics, 49(1): 94, 1998.

20. Nikkei Weekly, Sept. 20, 2004.

21. Makabe, Y., Plastics Age, 45(4): 119, 1999.

22. Hirai, A., and T. Hase, Japan Plastics, 55(1): 118, 2004.