Page 64 - Engineering Plastics Handbook

P. 64

38 Introduction

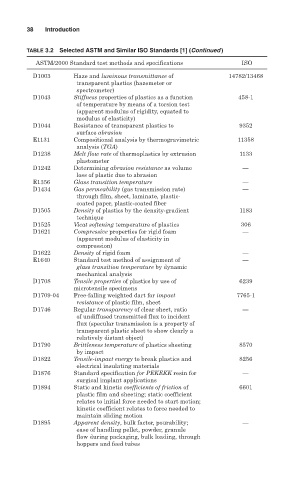

TABLE 3.2 Selected ASTM and Similar ISO Standards [1] (Continued)

ASTM/2000 Standard test methods and specifications ISO

D1003 Haze and luminous transmittance of 14782/13468

transparent plastics (hazemeter or

spectrometer)

D1043 Stiffness properties of plastics as a function 458-1

of temperature by means of a torsion test

(apparent modulus of rigidity, equated to

modulus of elasticity)

D1044 Resistance of transparent plastics to 9352

surface abrasion

E1131 Compositional analysis by thermogravimetric 11358

analysis (TGA)

D1238 Melt flow rate of thermoplastics by extrusion 1133

plastometer

D1242 Determining abrasion resistance as volume —

loss of plastic due to abrasion

E1356 Glass transition temperature —

D1434 Gas permeability (gas transmission rate) —

through film, sheet, laminate, plastic-

coated paper, plastic-coated fiber

D1505 Density of plastics by the density-gradient 1183

technique

D1525 Vicat softening temperature of plastics 306

D1621 Compressive properties for rigid foam —

(apparent modulus of elasticity in

compression)

D1622 Density of rigid foam —

E1640 Standard test method of assignment of —

glass transition temperature by dynamic

mechanical analysis

D1708 Tensile properties of plastics by use of 6239

microtensile specimens

D1709-04 Free-falling weighted dart for impact 7765-1

resistance of plastic film, sheet

D1746 Regular transparency of clear sheet, ratio —

of undiffused transmitted flux to incident

flux (specular transmission is a property of

transparent plastic sheet to show clearly a

relatively distant object)

D1790 Brittleness temperature of plastics sheeting 8570

by impact

D1822 Tensile-impact energy to break plastics and 8256

electrical insulating materials

D1876 Standard specification for PEKEKK resin for —

surgical implant applications

D1894 Static and kinetic coefficients of friction of 6601

plastic film and sheeting; static coefficient

relates to initial force needed to start motion;

kinetic coefficient relates to force needed to

maintain sliding motion

D1895 Apparent density, bulk factor, pourability; —

ease of handling pellet, powder, granule

flow during packaging, bulk loading, through

hoppers and feed tubes