Page 76 - Engineering Plastics Handbook

P. 76

50 Introduction

phenomena of creep and stress relaxation are time-dependent and

temperature-dependent. These viscoelastic phenomena are depicted with

the spring-and-dashpot models in Chap. 2, “Products and Designs.”

Creep is covered in ASTM D2990 (ISO 899-1,2), “Tensile, Compressive and

Flexural Creep and Creep-Rupture of Plastics,” and ISO/IEC (International

Electrotechnical Commission) 17025, “General Requirements for the

Competence of Calibration and Testing Laboratories.” Creep is defined in

ASTM D2990 as “the progressive deformation of a material at constant

load (stress).” Creep tests measure the dimensional changes under con-

stant load over a period of time, plotted at different constant temperatures.

Creep rupture tests are used to estimate the required time for rupture

under a constant load at different constant temperatures. ASTM D2990

(ISO 899-1,2) recognizes that creep values used in engineering design

should be determined under application-specific simulated conditions.

Application-specific conditions are obtained with CAD/CAE and proto-

types. Creep values are only estimates, and as with other engineering

plastics properties for long-term applications, safety factors are incorpo-

rated into the engineering data.

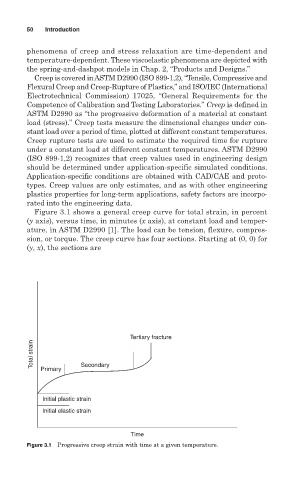

Figure 3.1 shows a general creep curve for total strain, in percent

(y axis), versus time, in minutes (x axis), at constant load and temper-

ature, in ASTM D2990 [1]. The load can be tension, flexure, compres-

sion, or torque. The creep curve has four sections. Starting at (0, 0) for

(y, x), the sections are

Tertiary fracture

Total strain

Primary Secondary

Initial plastic strain

Initial elastic strain

Time

Figure 3.1 Progressive creep strain with time at a given temperature.