Page 217 - Enhanced Oil Recovery in Shale and Tight Reservoirs

P. 217

200 Enhanced Oil Recovery in Shale and Tight Reservoirs

Table 8.2 Pump schedule in a Woodford shale frac. job (Grieser et al., 2007).dcont'd

Conc., Ibm/

Stage Vol., gal Fluid gal Proppant

22 Sand slug 14,240 Treated water 0.64 Premium

Brown-30/70

23 Sand slug 14,240 Treated water 0.73 Premium

Brown-30/70

24 Sand slug 14,240 Treated water 0.82 Premium

Brown-30/70

25 Sand slug 14,240 Treated water 0.9 Premium

Brown-30/70

26 Flush 3,655 Pad and flush

shale frac job. About 3% HCl was used in the acid pad. The total acid pad

volume was about one-third of the total fracturing fluid volume.

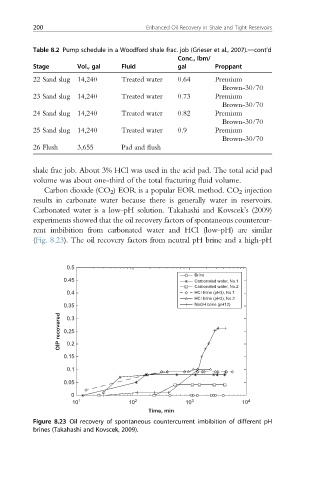

Carbon dioxide (CO 2 ) EOR is a popular EOR method. CO 2 injection

results in carbonate water because there is generally water in reservoirs.

Carbonated water is a low-pH solution. Takahashi and Kovscek’s (2009)

experiments showed that the oil recovery factors of spontaneous countercur-

rent imbibition from carbonated water and HCl (low-pH) are similar

(Fig. 8.23). The oil recovery factors from neutral pH brine and a high-pH

0.5

Brine

0.45 Carbonated water, No.1

Carbonated water, No.2

0.4 HCI brine (pH3), No.1

HCI brine (pH3), No.2

0.35 NaOH brine (pH12)

OlP recovered 0.25

0.3

0.2

0.15

0.1

0.05

0

10 1 10 2 10 3 10 4

Time, min

Figure 8.23 Oil recovery of spontaneous countercurrent imbibition of different pH

brines (Takahashi and Kovscek, 2009).