Page 59 - Enhanced Oil Recovery in Shale and Tight Reservoirs

P. 59

Huff-n-puff gas injection in oil reservoirs 47

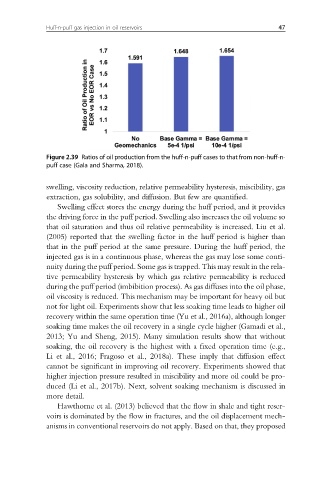

Figure 2.39 Ratios of oil production from the huff-n-puff cases to that from non-huff-n-

puff case (Gala and Sharma, 2018).

swelling, viscosity reduction, relative permeability hysteresis, miscibility, gas

extraction, gas solubility, and diffusion. But few are quantified.

Swelling effect stores the energy during the huff period, and it provides

the driving force in the puff period. Swelling also increases the oil volume so

that oil saturation and thus oil relative permeability is increased. Liu et al.

(2005) reported that the swelling factor in the huff period is higher than

that in the puff period at the same pressure. During the huff period, the

injected gas is in a continuous phase, whereas the gas may lose some conti-

nuity during the puff period. Some gas is trapped. This may result in the rela-

tive permeability hysteresis by which gas relative permeability is reduced

during the puff period (imbibition process). As gas diffuses into the oil phase,

oil viscosity is reduced. This mechanism may be important for heavy oil but

not for light oil. Experiments show that less soaking time leads to higher oil

recovery within the same operation time (Yu et al., 2016a), although longer

soaking time makes the oil recovery in a single cycle higher (Gamadi et al.,

2013; Yu and Sheng, 2015). Many simulation results show that without

soaking, the oil recovery is the highest with a fixed operation time (e.g.,

Li et al., 2016; Fragoso et al., 2018a). These imply that diffusion effect

cannot be significant in improving oil recovery. Experiments showed that

higher injection pressure resulted in miscibility and more oil could be pro-

duced (Li et al., 2017b). Next, solvent soaking mechanism is discussed in

more detail.

Hawthorne et al. (2013) believed that the flow in shale and tight reser-

voirs is dominated by the flow in fractures, and the oil displacement mech-

anisms in conventional reservoirs do not apply. Based on that, they proposed