Page 96 - Enhanced Oil Recovery in Shale and Tight Reservoirs

P. 96

Huff-n-puff injection in shale gas condensate reservoirs 83

From the above discussion of the problem, one easy way is to increase

the pressure near the wellbore or in the reservoir above the dew point

pressure by gas and/or water flooding (Hernandez et al., 1999). Surfactants

may be injected to reduce interfacial tension or alter wettability so that

residual liquid oil saturation is reduced (Kumar et al., 2006; Ahmadi et al.,

2011; Ganjdanesh et al. (2015). Solvents may be injected to mitigate the

impact of liquid blockage (Al-Anazi et al., 2005; Sayed and

Al-Munstasheri, 2014). These methods have been proposed for conven-

tional reservoirs. This chapter proposes huff-n-puff gas injection in shale

and tight reservoirs to mitigate the liquid condensate blocking. The method

is compared with solvent injection and surfactant treatment.

4.2 Experimental setup

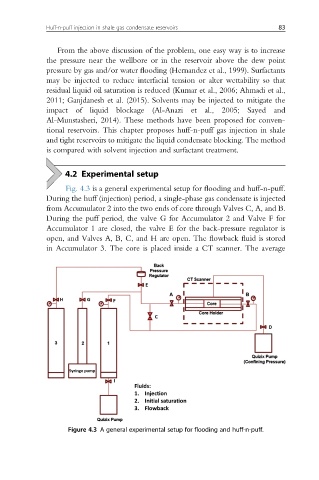

Fig. 4.3 is a general experimental setup for flooding and huff-n-puff.

During the huff (injection) period, a single-phase gas condensate is injected

from Accumulator 2 into the two ends of core through Valves C, A, and B.

During the puff period, the valve G for Accumulator 2 and Valve F for

Accumulator 1 are closed, the valve E for the back-pressure regulator is

open, and Valves A, B, C, and H are open. The flowback fluid is stored

in Accumulator 3. The core is placed inside a CT scanner. The average

Figure 4.3 A general experimental setup for flooding and huff-n-puff.