Page 112 - Facility Piping Systems Handbook for Industrial, Commercial, and Healthcare Facilities

P. 112

PIPING

2.62 CHAPTER TWO

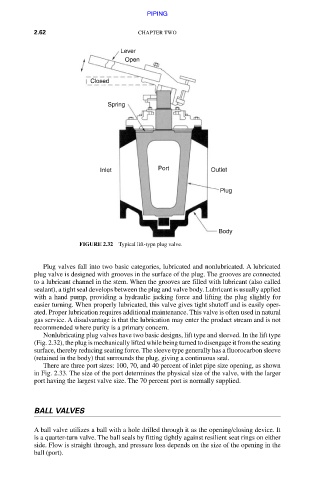

FIGURE 2.32 Typical lift-type plug valve.

Plug valves fall into two basic categories, lubricated and nonlubricated. A lubricated

plug valve is designed with grooves in the surface of the plug. The grooves are connected

to a lubricant channel in the stem. When the grooves are filled with lubricant (also called

sealant), a tight seal develops between the plug and valve body. Lubricant is usually applied

with a hand pump, providing a hydraulic jacking force and lifting the plug slightly for

easier turning. When properly lubricated, this valve gives tight shutoff and is easily oper-

ated. Proper lubrication requires additional maintenance. This valve is often used in natural

gas service. A disadvantage is that the lubrication may enter the product stream and is not

recommended where purity is a primary concern.

Nonlubricating plug valves have two basic designs, lift type and sleeved. In the lift type

(Fig. 2.32), the plug is mechanically lifted while being turned to disengage it from the seating

surface, thereby reducing seating force. The sleeve type generally has a fluorocarbon sleeve

(retained in the body) that surrounds the plug, giving a continuous seal.

There are three port sizes: 100, 70, and 40 percent of inlet pipe size opening, as shown

in Fig. 2.33. The size of the port determines the physical size of the valve, with the larger

port having the largest valve size. The 70 percent port is normally supplied.

BALL VALVES

A ball valve utilizes a ball with a hole drilled through it as the opening/closing device. It

is a quarter-turn valve. The ball seals by fitting tightly against resilient seat rings on either

side. Flow is straight through, and pressure loss depends on the size of the opening in the

ball (port).

Downloaded from Digital Engineering Library @ McGraw-Hill (www.accessengineeringlibrary.com)

Copyright © 2009 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.